Embarking on the development of a new food processing facility is a monumental task involving complex engineering, procurement, and project management. For entrepreneurs and established corporations alike, the turnkey model offers a streamlined path from concept to a fully operational plant. This guide provides a comprehensive overview of turnkey food processing plants, detailing the end-to-end process, key benefits, and critical considerations for launching a successful project with a trusted engineering partner.

What is a Turnkey Food Processing Plant?

A turnkey food processing plant is a comprehensive, end-to-end project delivered by a single, expert provider. In this model, the partner assumes full responsibility for the entire project lifecycle, from initial design and equipment manufacturing to on-site installation and final commissioning. The core promise is simplicity and accountability: you are handed the “keys” to a facility that is fully complete and ready to begin production.

The ‘Single Window Solution’ Explained

The term “single window solution” is central to the turnkey concept. It means that you, the client, have one dedicated partner managing every stage of the project. This approach eliminates the immense challenge of coordinating multiple vendors, contractors, and consultants. It streamlines communication, simplifies decision-making, and establishes a clear line of accountability, ensuring that every component of the plant works in perfect harmony.

Key Components Included in a Turnkey Project

A truly comprehensive turnkey solution integrates several critical services into one seamless package. While specific deliverables vary by project scope, the core components typically include:

- Process Flow Design and Plant Layout: Detailed engineering blueprints that map out every stage of production for maximum efficiency and compliance.

- Manufacturing and Supply of All Machinery: The fabrication and procurement of every piece of equipment, from core processing units to ancillary systems.

- On-site Installation and System Integration: The physical installation of all machinery, including electrical, plumbing, and automation systems, to create a cohesive production line.

- Staff Training and Operational Handover: Comprehensive training for your operational team on equipment use, maintenance protocols, and safety procedures before the final handover.

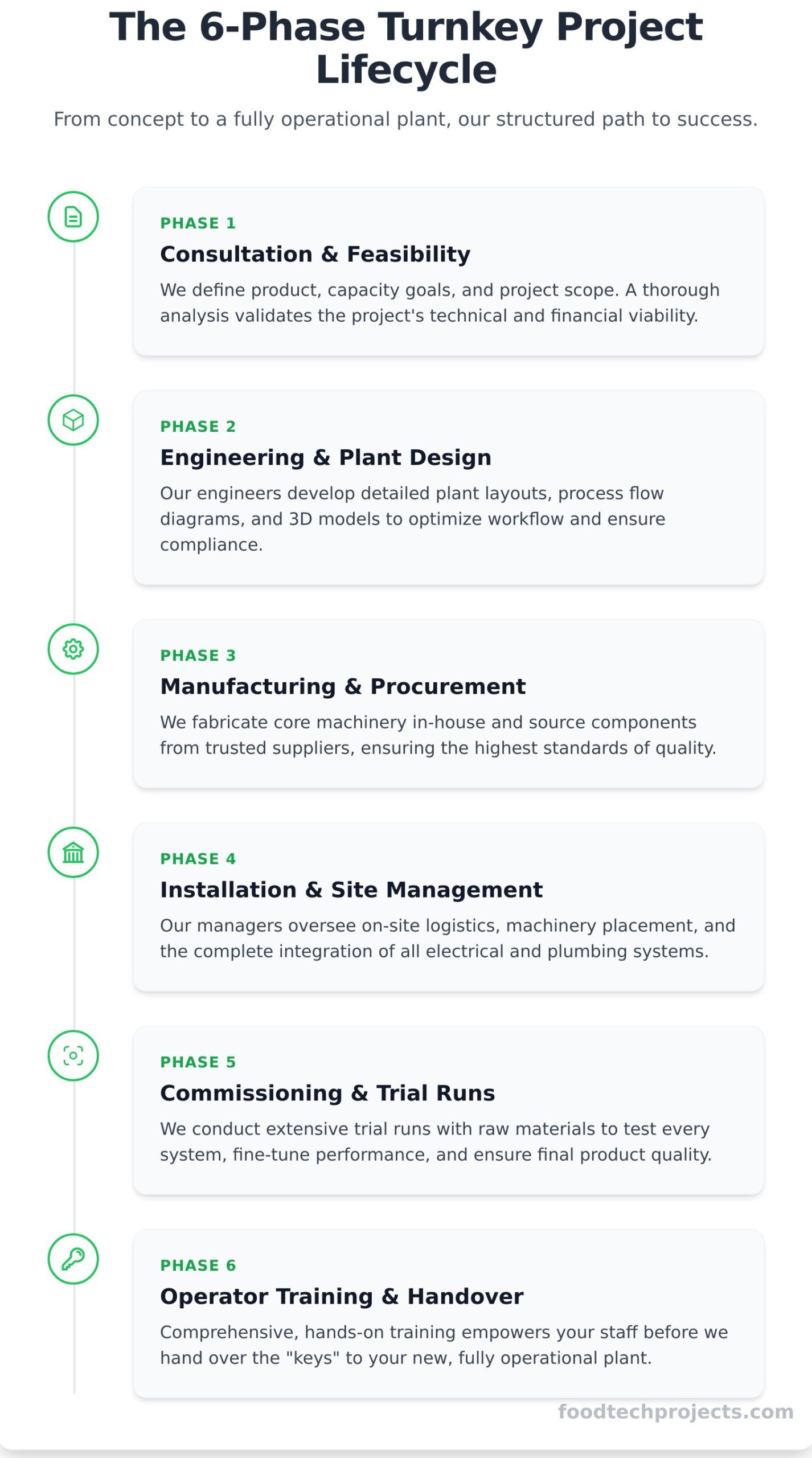

The 6 Phases of a Turnkey Project Lifecycle

Our structured, six-phase approach ensures complete transparency and project success. We guide our clients through a meticulous process that transforms an initial idea into a high-performance, fully operational food processing plant.

Phase 1: Consultation and Feasibility Study

This foundational stage begins with a deep dive into your vision. We work closely with you to define the product, establish production capacity goals, and outline the scope of the project. Our team conducts a thorough analysis of technical requirements and budgetary constraints, culminating in a preliminary project report that validates the project’s viability.

Phase 2: Process Engineering and Plant Design

With a clear concept, our engineers develop detailed plant layouts, process flow diagrams, and 3D models. This phase is critical for optimizing space, ensuring logical workflow, and finalizing all machinery specifications. Every design element is meticulously planned to comply with international food safety standards and local regulations.

Phase 3: Equipment Manufacturing and Procurement

Once the design is approved, we initiate the manufacturing of core machinery at our advanced facilities. Our direct control over fabrication ensures the highest standards of quality and precision. Simultaneously, we procure any necessary ancillary components from our network of trusted suppliers, subjecting every item to rigorous quality control checks.

Phase 4: Installation and Site Management

Our project management team coordinates the logistics of shipping all equipment to your site. On location, our experienced supervisors manage the complete installation process, overseeing everything from civil work coordination to the precise placement and integration of machinery, including all electrical and plumbing connections.

Phase 5: Commissioning and Operator Training

This is the final stage before handover, where we bring the plant to life. We conduct extensive trial runs with raw materials to test every system, fine-tune performance, and ensure the final product meets your quality specifications. Concurrently, we provide hands-on training for your operators and maintenance staff, empowering them to run the plant efficiently and safely from day one.

Core Advantages of the Turnkey Model

Choosing a turnkey solution is an investment in a guaranteed outcome, not just a collection of machines. The strategic benefits of partnering with a single, expert provider are significant and directly impact your project’s success and long-term profitability.

Single Point of Accountability and Reduced Risk

With a turnkey project, one partner is wholly responsible for delivering the final result. This eliminates the risk of disputes between different suppliers or contractors, which can cause costly delays and complications. Problem-solving is streamlined, communication is simplified, and you have a single point of contact dedicated to your project’s success.

Cost and Time Efficiency

A turnkey contract typically operates on a fixed project cost, providing you with budget certainty from the outset. Because planning, manufacturing, and installation are integrated, the project timeline is significantly shorter compared to managing multiple vendors. This integrated approach helps avoid costly delays and ensures a faster path to revenue generation.

Access to Specialized Expertise and Technology

Partnering with an experienced turnkey provider gives you immediate access to decades of specialized engineering knowledge. You can leverage proven plant designs, advanced processing technologies, and industry best practices to ensure your facility operates at optimal efficiency and produces a high-quality product consistently.

Why Choose Food Tech Projects as Your Turnkey Partner?

With a global reputation for engineering excellence, Food Tech Projects is your ideal partner for complex food processing ventures. We offer over 35 years of global experience, delivering successful projects across diverse food sectors. Our state-of-the-art in-house manufacturing facilities give us unparalleled control over quality, while our proven track record demonstrates our commitment to delivering on our promises. Discuss your project with our experts.

Types of Turnkey Plants We Deliver

Our engineering expertise covers a wide and diverse range of food processing industries. We design and deliver custom turnkey solutions tailored to your specific product and market needs.

Spice and Masala Processing Lines

We deliver complete, automated plants for producing high-quality spices and masalas. These solutions cover every stage, from raw material cleaning and drying to precision grinding, blending, and final packaging for retail and bulk markets.

Fruit & Vegetable Dehydration Plants

Our turnkey solutions for fruit and vegetable processing include advanced industrial dryers designed to produce premium dried fruits, vegetables, and powders. We engineer complete lines that manage washing, slicing, blanching, dehydration, and packaging.

Coconut Processing Plants

We specialize in end-to-end solutions for the coconut industry, delivering complete plants for producing desiccated coconut powder, virgin coconut oil, and other value-added products. Our lines cover every process from de-husking and de-shelling to drying and oil extraction.

Frequently Asked Questions

What is the typical timeline for a turnkey food processing project?

The timeline varies depending on the project’s complexity and scale, but a typical project can range from 6 to 18 months from initial consultation to final commissioning.

Is a turnkey solution more expensive than sourcing equipment individually?

While the initial quote may seem higher, a turnkey solution often provides greater value by eliminating hidden costs, reducing project delays, and ensuring seamless integration, which leads to lower total cost of ownership.

What information do I need to provide to get a quote?

To provide an accurate quote, we need to understand your desired final product, target production capacity (e.g., kg/hour), available facility space, and any specific processing requirements.

Do you provide after-sales support and spare parts?

Yes, we offer comprehensive after-sales support, including readily available spare parts and technical assistance to ensure your plant operates with minimal downtime.

Can you handle projects in my country?

Absolutely. Food Tech Projects has a global footprint with successful plant installations in over 20 countries, and we are experienced in managing international logistics and compliance.

If you are ready to transform your vision for a food processing facility into a reality, our team of engineers is prepared to assist you. By choosing a turnkey solution, you are investing in a partnership dedicated to your success, ensuring your plant is delivered on time, within budget, and to the highest quality standards. Request a Consultation for Your Turnkey Plant and take the first step towards building your state-of-the-art production facility.