ROTARY DRUM DRYER

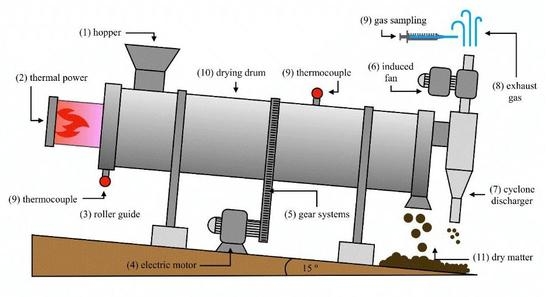

Gemtech rotary drum dryer is a type of industrial dryer that is used to reduce the moisture content of a material. It typically consists of a rotating cylindrical drum that is partially enclosed and heated. The material to be dried is fed into the drum and as it rotates, it comes into contact with the hot surfaces of the drum and the hot air that is circulated through the drum. The moisture in the material evaporates and is removed from the drum through a exhaust system. Gemtech Rotary drum dryers are used in a wide range of industries, including agriculture, food processing, and mineral processing to dry a variety of materials such as grains, fertilizers, wood chips, and minerals.

APPLICATIONS OF GEMTECH ROTARY DRUM DRYER

Rotary drum dryers are used in a wide range of industries for drying a variety of materials. Some of the common applications include:

- Agriculture: Rotary drum dryers are used to dry crops such as corn, wheat, and soybeans, as well as forage and other plant-based materials.

- Food Processing: Rotary drum dryers are used to dry food products such as coffee beans, tea leaves, fruits, and vegetables.

- Wood Products: Rotary drum dryers are used to dry wood chips and sawdust for use in the production of wood pellets and other wood products.

- Mineral Processing: Rotary drum dryers are used to dry minerals such as ores, sands, and potash.

- Chemical Processing: Rotary drum dryers are used to dry chemicals such as fertilizers, pesticides, and other industrial chemicals.

- Pharmaceuticals: Rotary drum dryers are used to dry pharmaceutical products such as powders, granules, and other solid forms of medication.

- Recycling: Rotary drum dryers are used to dry various materials that can be recycled such as plastic, paper, and waste materials.

- Biomass: Rotary drum dryers are used to dry biomass such as straw, sawdust, bagasse, and other plant-based materials that are used as a source of energy.

ADVANTAGES OF GEMTECH ROTARY DRUM DRYER

There are several advantages of using a rotary drum dryer:

- High Efficiency: Rotary drum dryers are very efficient at removing moisture from materials, which can result in significant cost savings and increased productivity.

- Versatility: Rotary drum dryers can handle a wide range of materials with different moisture contents, sizes, and shapes.

- Large Capacity: Rotary drum dryers can be designed with large capacities to handle high-volume drying needs.

- Low Maintenance: Rotary drum dryers are designed for low maintenance and easy operation, which can result in lower operating costs.

- Low Energy Consumption: Rotary drum dryers can be designed to operate with low energy consumption, which can result in lower operating costs.

- Low Pollution: Rotary drum dryers are designed to minimize pollution, which can reduce environmental impact.

- Reliability: Rotary drum dryers are designed for long-term use and can be built with high-quality materials and components to increase reliability and durability.

- Customizable: Rotary drum dryers can be customized to meet specific requirements, such as temperature and humidity control, to optimize the drying process.