WORKING PRINCIPLE OF HEAT PUMP DRYER

Conventionally, materials are dried either in the field (sun drying) or using high temperature dryers(electric, gas fired, etc.). Successful outdoor drying depends upon good weather and indeterminate weather can render a product worthless. High temperature drying can damage the nutrient content and impart an unpleasant smell to the dried product. Specialty crops such as ginseng, herbs, echinacea, etc., need to be dried at low temperatures (30 – 45Celsius degree) for product quality optimization. This is an important consideration as they have a relatively high commercial value. Heating ambient air to use for drying, although a simple cost-effective procedure, is of limited application, particularly at higher ambient air relative humidity’s because of the low allowable maximum temperature conditions. Under high ambient moist air conditions, it may not even be possible to dry the material by conventional means. High temperature drying deteriorates the material structure and can render it unsuitable for further use. Low temperature drying of specialty crops reduces the risk of loss in nutrient content and damage to physical properties. Drying system incorporating a dehumidification cycle have been developed that both conserve energy and handle the material gently. The dryer operates using a heat pump where both sensible and latent heats are recovered from the exhaust air. The heat is then recycled back through the dryer by heating the air entering the dryer. The GEM heat pump drying system is a combination of two sub- systems: a heat pump and a dryer, also the equipment have 2 times waste heat recovery.

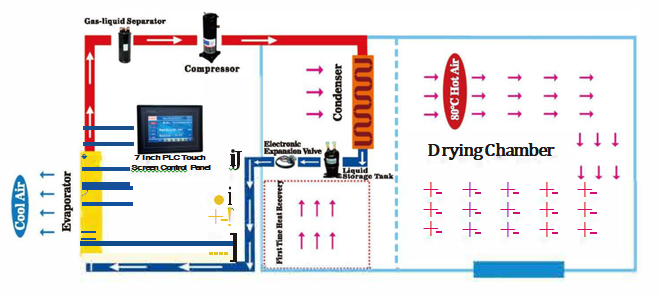

GEM heat pump dryer operates according to a basic air conditioning cycle involving four main components: the evaporator, the compressor, the condenser and the expansion valve. The working fluid (refrigerant) at low pressure is vaporized in the evaporator by heat drawn from the dryer exhaust air. The compressor raises the enthalpy of the working fluid of the heat pump and discharges it as superheated vapor at high-pressure. Heat is removed from the working fluid and returned to the process air at the condenser. The working fluid is then throttled to the low-pressure line (using an expansion valve) and enters the evaporator to complete the cycle. In the dryer system, hot and dry air at the exit of condenser is allowed to pass through the drying chamber where it gains latent heat from the material. The humid air at dryer exit then passes through the evaporator where condensation of moisture occurs as the air goes below dew point temperature. Then drain the condenser water.

HEAT PUMP DRYER APPLICATION

Drying Herbs:

Pseudo-ginseng, Aniseed, Radix Morinder Officinalls, Dendrobe, Yam, Glossy Ganoderma, Honeysuckle Flower, Cassia, Ginseng, Ginger, Maca, Chinese Wolfberry, Chinese Angelica Root, Chrysanthemum Flower,Kava

Drying Agriculture Products:

Dragon Fruit Flower, Rose, Mushroom, Edible Fungus, Sweet Potatoes, Okra, Tobacco Leaf, White Fungus, Edible Tree Fungus, Red Pepper, Daylily, Agrocybe Aegerita, Dried Vegetables, Bamboo Shoot, Cassava, Garlic, Tomato, Onion.

Drying Fruit:

Longan, Litchi, Banana, Mango, Date, Waxberry, Plum, Lemon, Raisin, Artocarpus Heterophyllus Lam, Kiwi Fruit, Dried Persimmon, Olive, Candied Fruits, Apple, Fig, Pineapple, Strawberry, Blueberry, Grape, Coconut.

Drying Food:

Sausage, Preserved Pork, Smoked Fish, Intestine And Casing, Rice Noodle, Noodle, Beancurd Sticks, Corn, Grain, Nut. Seed, Seaweed.

Drying Seafood:

Sea Fish, Squid, Shrimp, Seaear, Cuttlefish, Sea Cucumber, Catfish, Anchovy Fish.

Drying Tea:

Black Tea, Red Tea, Flower Tea Etc.

Drying Incense:

Incense, Mosquito Incense, Etc.

Drying Wood:

Pine, Redwood, Redwood Furniture, Bamboo Products, Etc.

GEMTECH HEAT PUMP DRYER FEATURES

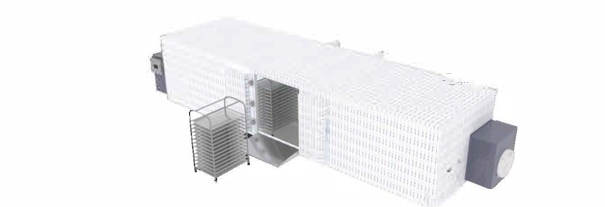

Easy to Install

The machine and chamber are easy to install, and the overall machine needs small footprint. It can be installed indoors and outdoors.

Efficient and Eco-friendly

The machine absorbs plenty of energy of the air, only consumes a little electric energy. The power consumption is only 1/3-1/4 of the electric heating, compared with other fuels, such as coal, oil, gas etc., ii can save about 75% of operating costs. 1 KWH of electricity can achieve 4 KWH efficiency.

Safe and Reliable Operation

The whole system is operated in an absolutely safe and reliable semi-closed drying system. There are no hidden dangers of flammable, explosive, poisoning and short circuit of traditional dryers, such as other dryers that powered by fuel, gas, and electric heating.

Long Service Life and Low Maintenance Cost

The machine is developed on the basis of traditional air conditioning technology, with mature technology, stable and reliable performance and long service life.

Automation and lntelligentization

Fully automatic intelligent control system and free of labor costs. It uses self-controlled thermost and dries for 24 hours continuously.

Wide Range of Applications, Not Affected by the Climate

Widely used in food, chemical, pharmaceutical, paper, leather, wood, agricultural sideline products processing and other industries heating and drying.

Compressor:

It adopts the world famous brand Copeland top-grade flexible scroll compressor, which has functions such as low wear resistance, long service life, over-current protection, over-temperature protection, strong liquid-resistant resistance, high and low voltage protection. The Copeland compressor has a built-in pressure relief valve inside the body, which can automatically relieve pressure to the low pressure end when the high pressure is too high.

Electronic Expansion Valve:

Introducing the latest technology from Japan and the company’s outstanding control system, we have developed a unique electronic expansion valve control method, using digital technology to control the working fluid to achieve the best flow rate effect, thereby increasing the COP value.

Evaporator:

The use of a hydrophilic film aluminum foil does not cause oxidative detachment even after long-term use of the hydrophilic layer. This type of evaporator has a special advantage, excellent water exchange performance, can reduce wind.