Understand the different types of machines for oil extraction, from small-scale presses to complete industrial plants, to make an informed investment for your business. When searching for a “machine for oil,” you will encounter a vast range of equipment, from small countertop appliances to massive industrial installations. This guide clarifies the different scales of technology to help you navigate the options and identify the right solution for your production goals.

Understanding Oil Machines: A Spectrum of Solutions

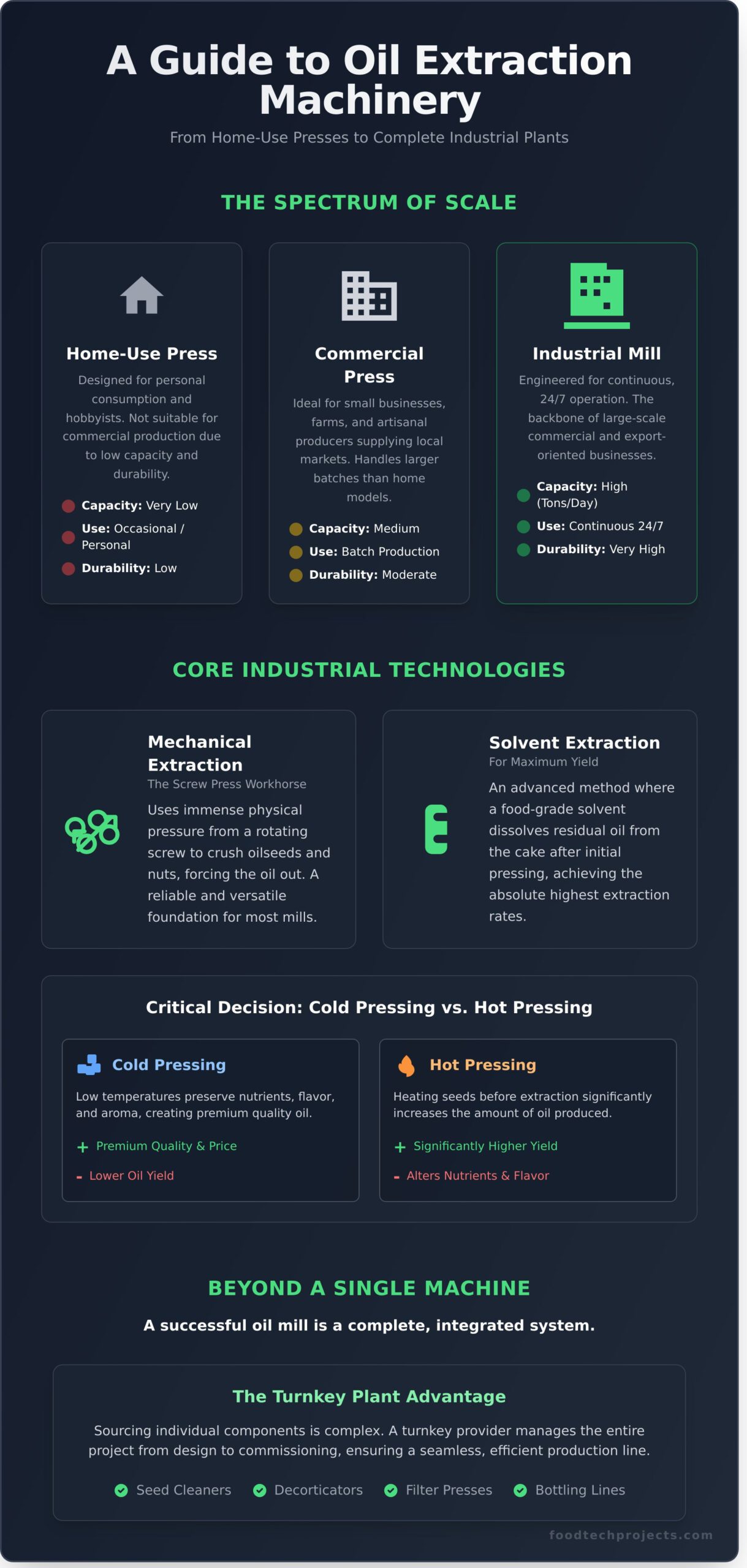

The term ‘machine for oil’ covers vastly different equipment scales, each designed for a specific purpose and production volume. Understanding these distinctions is the first step toward making a sound investment. The market can be segmented into three primary categories: home-use, commercial, and industrial. Matching the machine scale to your business goals is critical for efficiency, durability, and profitability.

Category 1: Home-Use Oil Presses

These machines are designed for personal consumption and small, occasional batches. Typically, they are compact, countertop-sized appliances with a low processing capacity. While excellent for hobbyists or for producing fresh oil for family use, they are not suitable for any level of commercial production. Their construction lacks the durability required for continuous operation, and their output is far too low to be commercially viable.

Category 2: Commercial Oil Press Machines

Built for small businesses, farms, and artisanal producers, commercial oil presses represent a step up in both capacity and durability. These machines can handle larger batches and more frequent use than home models. They are ideal for businesses that supply local markets, specialty food stores, or restaurants. While robust, they are still primarily designed for batch production rather than the continuous, 24/7 operation required in large-scale industrial settings.

Category 3: Industrial Oil Mill Machinery

Engineered for continuous, large-scale oil production, industrial machinery is the focus for any serious commercial or export-oriented business. This equipment is not a standalone unit but rather a critical component within a complete, integrated processing plant. These systems are designed for high throughput, maximum efficiency, and long-term reliability, forming the backbone of the global edible oil industry.

Core Technologies in Industrial Oil Extraction

The extraction method you choose directly impacts oil yield, quality, and overall profitability. In the industrial sector, several core technologies are employed to process raw materials efficiently and effectively. An overview of these primary technologies will help clarify which process is best suited for your needs.

Mechanical Extraction: The Power of the Screw Press

An oil expeller, commonly known as a screw press machine, is the workhorse of mechanical extraction. This technology uses a rotating screw to crush oilseeds and nuts under immense pressure, physically forcing the oil out. It is an ideal and versatile method for a wide range of raw materials, including sunflower seeds, rapeseed, peanuts, and sesame. The screw press is the foundation of most small to large-scale oil mills due to its reliability and effectiveness.

Solvent Extraction for Maximum Yield

For operations focused on achieving the absolute highest extraction rates, solvent extraction is the advanced method of choice. After an initial pressing, the remaining oil cake is treated with a food-grade solvent that dissolves the residual oil. The oil is then separated from the solvent, which is recycled for reuse. This method is commonly used for high-volume oilseeds like soybean and sunflower, where maximizing yield is a primary economic driver.

Cold Pressing vs. Hot Pressing: A Critical Decision

The temperature during extraction is a critical decision that affects the final product. Cold pressing involves processing seeds at low temperatures, which preserves the natural nutrients, flavour, and aroma, resulting in premium-quality oils that command a higher market price. In contrast, hot pressing involves heating the seeds before extraction, which significantly increases the oil yield but can alter the oil’s properties and nutritional profile. The choice between these methods depends entirely on your target market and desired product quality.

Selecting the Right Industrial Oil Mill Machinery: Key Factors

Choosing an industrial machine is a major capital investment that will define your operational capabilities for years. It is essential to evaluate critical technical and operational factors before making a purchase to ensure your equipment aligns perfectly with your production targets and quality standards.

Essential Machine Specifications to Analyze

When evaluating industrial machinery, move beyond the price tag and focus on the specifications that determine performance and long-term value. Key factors include:

- Processing Capacity (Tons Per Day): Ensure the machine’s throughput matches your business plan and raw material availability.

- Raw Material Compatibility: Confirm that the equipment is specifically designed or can be configured to efficiently handle your target seeds or nuts.

- Power Consumption & Efficiency: This is a major factor in your ongoing operational costs and directly impacts your profitability.

- Build Quality & Material: Look for robust construction, preferably with stainless steel contact parts for food-grade hygiene and long-term durability.

Beyond a Single Machine: The Turnkey Plant Advantage

A successful oil mill is far more than just a press; it’s a complete, integrated system where every component works in harmony. Essential ancillary equipment includes seed cleaners, decorticators (for shelling), filter presses, and bottling lines. Attempting to source and integrate these components individually can be complex and inefficient. This is why a “single window solution” from an experienced partner is critical for success. A turnkey provider manages the entire project, from design and manufacturing to installation and commissioning, ensuring a seamless and efficient production line. If you are serious about industrial production, it is vital to think in terms of a complete plant, not just a single machine. Request a consultation for your turnkey oil mill project.

Frequently Asked Questions

What is the difference between an oil press and an oil expeller?

The terms “oil press” and “oil expeller” are often used interchangeably, especially in the context of industrial screw presses. Both refer to machinery that uses mechanical pressure to extract oil from seeds and nuts. “Expeller” specifically highlights the action of expelling oil via a screw mechanism.

Can one industrial machine process different types of oil seeds?

Many industrial screw presses are versatile and can be adapted to process different types of oilseeds. However, optimal performance often requires specific adjustments or changes to components like the screw configuration or press cage to match the size, hardness, and oil content of the raw material.

How much does a complete industrial oil mill plant cost?

The cost of a complete industrial oil mill plant varies significantly based on its processing capacity, the level of automation, the type of raw material, and the specific equipment included. A small-scale plant may start in the tens of thousands of dollars, while large, fully automated plants can be a multi-million dollar investment.

What is the average oil yield I can expect from sunflower seeds?

The oil yield from sunflower seeds depends on the seed variety and the extraction method. Generally, with a high-quality industrial screw press, you can expect a yield of 35% to 45%. A solvent extraction plant can increase this yield further.

What is the first step to starting an edible oil processing business?

The first step is to conduct a thorough feasibility study. This includes analyzing your target market, securing a reliable supply of quality raw materials, developing a comprehensive business plan, and understanding the regulatory requirements in your region.

Do you provide installation and training for your machinery?

Yes, as a provider of turnkey solutions, we offer complete project support, which includes machinery installation, commissioning, and operational training for your staff to ensure your plant runs smoothly and efficiently from day one.

Making the right choice in oil extraction machinery is fundamental to your business’s success. With over 35 years of industry experience and successful turnkey project installations across the globe, we have an uncompromising commitment to engineering quality and performance. We provide comprehensive, end-to-end solutions for your edible oil processing needs. Enquire Now for a Customised Oil Mill Plant Solution and let our experts design a system that delivers precision, power, and performance for your business.