Oil mills are fundamental to the global food industry, serving as the critical link between oil-bearing raw materials and the final edible oils used in kitchens and manufacturing plants worldwide. From ancient stone presses to modern, automated factories, the technology of oil extraction has evolved significantly. This comprehensive guide explores everything you need to know about oil mills, from their basic functions and history to the key considerations for selecting the right machinery for commercial production.

What is an Oil Mill?

An oil mill is an industrial facility dedicated to the extraction of oil from oilseeds and other oil-rich vegetable matter. The primary purpose is to crush, press, or otherwise process raw materials like sunflower seeds, soybeans, peanuts, coconuts, or olives to separate the oil from the solid components. The resulting crude oil is then often refined for consumption, while the leftover solid material, known as press cake or meal, is typically utilized as animal feed due to its high protein content. Modern oil mills range from small-scale community operations to large, fully integrated industrial plants.

Types of Oil Mills

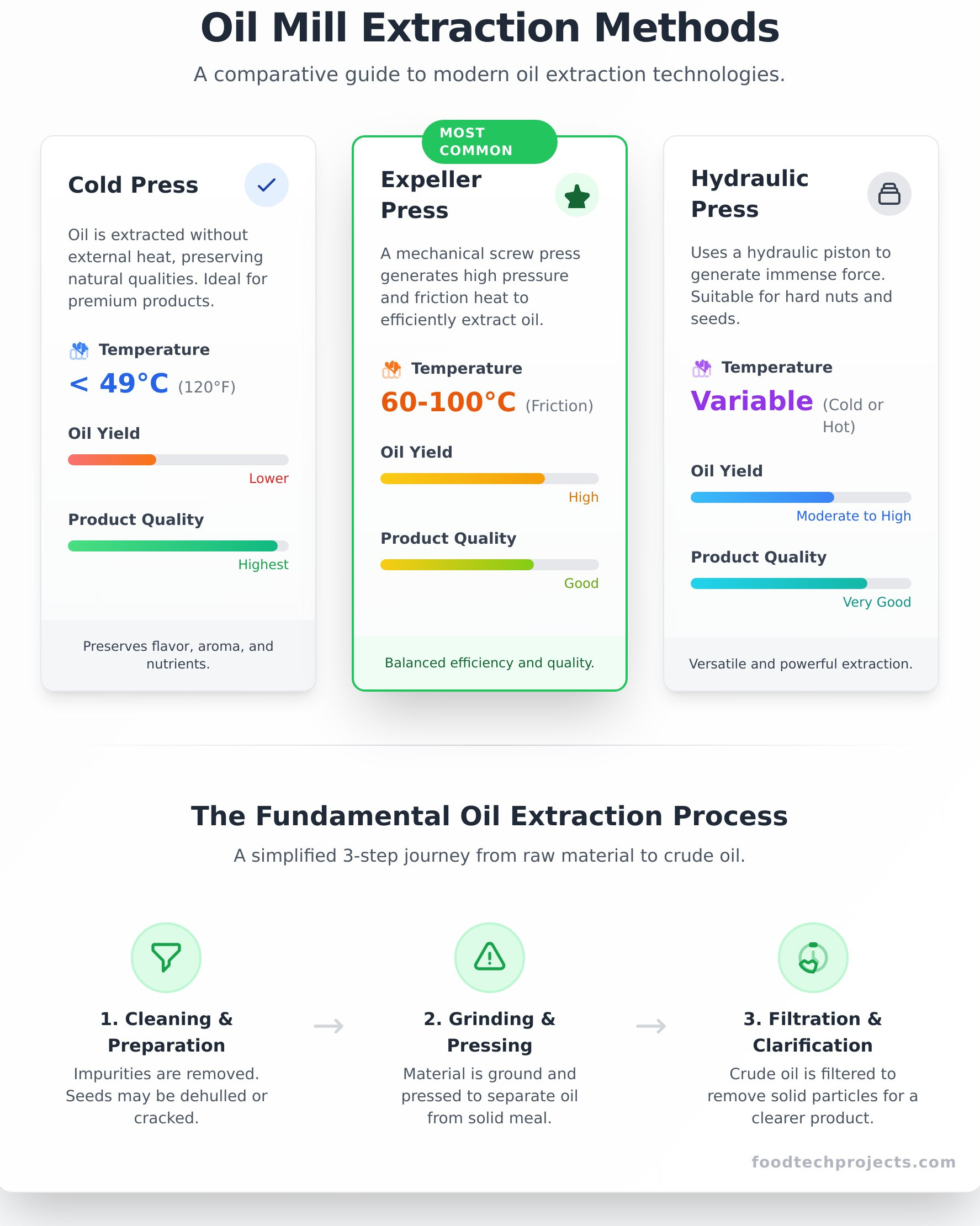

The technology employed in an oil mill defines its process, efficiency, and the quality of the final product. The primary types are distinguished by their extraction methods:

- Cold Press Oil Mills: This method involves extracting oil without applying external heat, typically keeping temperatures below 49°C (120°F). The main advantage is that it preserves the natural flavor, aroma, and nutritional profile of the oil. Cold-pressed oils are considered premium products but the yield is generally lower than other methods.

- Expeller Oil Mills: Also known as screw pressing, this is a common mechanical extraction method. An expeller press uses a rotating screw to exert immense pressure on the raw material inside a barrel, forcing the oil out through small openings. While this process generates heat from friction, it is highly efficient for a wide range of seeds and nuts.

- Hydraulic Oil Mills: This method utilizes a hydraulic press to generate the force needed for extraction. The raw material is placed in a cage and subjected to high pressure from a piston. It is often used for harder nuts and seeds and can be part of both cold and hot pressing operations.

The Oil Extraction Process

Regardless of the specific machinery, the fundamental steps in oil extraction are consistent. The process is designed to maximize oil yield while maintaining the desired quality standards.

- Cleaning and Preparation: Raw materials are first cleaned to remove impurities like dirt, stones, and metal debris. Depending on the seed, they may also be dehulled or cracked.

- Grinding and Pressing: The prepared seeds are ground into a coarse meal or paste to rupture the oil cells. This material is then fed into the press (expeller, hydraulic, etc.) where immense pressure is applied to separate the crude oil from the solid meal.

- Filtration and Clarification: The extracted crude oil contains fine solid particles. It is passed through filters or centrifuges to remove these impurities, resulting in a clearer, more stable product. Further refining may be required depending on the end-use.

History of Oil Mills

The practice of extracting vegetable oil dates back thousands of years. Early civilizations relied on rudimentary but effective methods to obtain this valuable commodity for cooking, lighting, and medicinal purposes. The evolution from these ancient techniques to today’s high-tech facilities showcases remarkable engineering progress.

Historical Techniques

The earliest oil mills were simple, manually operated devices. Large stone mortars and pestles were used to crush olives and seeds. A significant advancement was the development of the edge runner stone, a large, wheel-shaped stone that rotated in a circular trough to grind the material. This was often powered by draft animals like oxen or donkeys, dramatically increasing production capacity over manual methods.

Modern Innovations

The Industrial Revolution introduced steam power, and later electricity, which revolutionized oil milling. Mechanical screw presses replaced animal-powered mills, leading to greater efficiency and higher yields. Today, modern oil mills are highly automated, featuring sophisticated control systems that monitor temperature, pressure, and flow rates to ensure consistent quality and maximum output. There is also a growing emphasis on sustainability, with innovations focused on energy efficiency and minimizing waste.

Choosing the Right Oil Mill for Your Needs

Selecting the appropriate oil mill machinery is a critical decision that impacts production capacity, operational efficiency, and profitability. A thorough evaluation of your business requirements and the available technology is essential for making an informed choice.

Key Features to Look For

When investing in oil mill equipment, several technical and operational features should be prioritized:

- Energy Efficiency: Modern machinery is designed to minimize power consumption, which directly impacts operational costs. Look for equipment with high-efficiency motors and optimized designs.

- Ease of Maintenance and Durability: The machinery should be constructed from high-quality, durable materials to withstand continuous operation. Designs that allow for easy access to parts for cleaning and maintenance will reduce downtime.

- Manufacturer Support and Service: Partner with a manufacturer that offers comprehensive support, including installation, commissioning, training, and readily available spare parts. A reliable service partner is invaluable for long-term success.

Cost Considerations

The setup of an oil mill involves significant capital investment. It is crucial to look beyond the initial purchase price and consider the total cost of ownership. This includes installation, operational costs (energy, labor), maintenance, and potential returns. While a lower initial investment might be tempting, higher-quality, more efficient machinery often provides a better return on investment over the long term through lower operating costs and higher product quality.

Economic Benefits of Oil Mills

Establishing an oil mill can be a highly profitable venture, contributing to both business growth and local economic development. The global demand for edible oils is consistently strong, and producing high-quality products can secure a stable position in the market.

Market Trends in Edible Oils

Consumer preferences are increasingly shifting towards healthy, natural, and locally sourced food products. This trend has fueled demand for cold-pressed and specialty oils, such as avocado, grapeseed, and nut oils. An oil mill can capitalize on these trends by producing premium products for niche markets, often commanding higher prices.

Case Studies of Successful Operations

Across the globe, numerous businesses have achieved success by investing in modern oil milling technology. From small-scale operations producing artisanal olive oil to large industrial plants supplying major food brands, the key to success often lies in efficient production, consistent quality control, and a strong understanding of market demands. These operations not only generate profits but also create jobs and support local agriculture.

Frequently Asked Questions

What are the different types of oil mills available?

The main types of oil mills are categorized by their extraction method: cold press mills, which preserve nutrients without heat; expeller (or screw press) mills, which use mechanical pressure and friction; and hydraulic mills, which use a piston to exert force.

How does the oil extraction process work?

The process generally involves cleaning the raw materials, grinding them into a paste or meal to break down oil cells, pressing the material to separate the oil from the solid meal, and finally filtering the crude oil to remove impurities.

What should I consider before setting up an oil mill?

Key considerations include the type of raw material you will process, your desired production capacity, the technology and efficiency of the equipment, the total cost of investment, and the level of support provided by the machinery manufacturer.

What are the economic advantages of owning an oil mill?

Owning an oil mill can be highly profitable due to the consistent global demand for edible oils. It allows for value addition to agricultural products, creates employment opportunities, and can cater to growing markets for healthy and specialty oils.

How can I ensure the quality of oil produced in my mill?

Oil quality is ensured by using high-quality raw materials, maintaining strict cleanliness throughout the process, controlling parameters like temperature and pressure during extraction, and employing effective filtration methods.

Embarking on an oil mill project requires expertise, precision engineering, and a reliable technology partner. With over 35 years of experience, Food Tech Projects stands as a global supplier of turnkey food processing solutions, offering comprehensive support from design to installation. Our commitment to quality ensures you receive robust, efficient, and reliable machinery tailored to your specific production needs. To take the next step in establishing your successful oil extraction operation, we invite you to Get a quote for your oil mill project today!