In industrial processing, achieving a precise and consistent particle size is paramount for product quality, performance, and efficiency. The pulverizer machine is a cornerstone of this process, engineered for fine and ultra-fine size reduction of a vast range of materials. This guide provides a comprehensive overview of pulverizer technology, common types, and the critical criteria for selecting the right machine to meet your specific production requirements, ensuring you make an informed investment in your processing line.

What is a Pulverizer Machine and How Does It Work?

An industrial pulverizer is a high-speed grinding machine designed to reduce solid materials into fine, uniform powders. Unlike crushers, which handle primary, coarse size reduction, or grinders that produce medium-sized particles, a pulverizer specializes in the final stage of milling to achieve a very fine mesh size. The process relies on a combination of core mechanical principles: impact (high-speed collision), attrition (friction between particles), and shearing (cutting or tearing action) to break down materials effectively.

The Fundamental Working Principle of Industrial Pulverizers

The operation of a typical industrial pulverizer follows a systematic and controlled process to ensure consistent output. While designs vary, the core principle remains consistent across most models:

- Material Feeding: Raw material is introduced into the grinding chamber at a controlled rate through a hopper, often using a rotary feeder or screw conveyor to prevent overloading and ensure a steady flow.

- High-Speed Impact: Inside the chamber, a rotor assembly fitted with hammers, pins, or blades rotates at extremely high speeds, striking the material with immense force.

- Particle Size Reduction: The initial impact shatters the material. These smaller particles then collide with each other and the chamber’s serrated liner plates, undergoing further reduction through attrition and shearing forces.

- Classification and Discharge: A screen or an internal air classifier retains oversized particles in the grinding zone for further processing, allowing only the powder that meets the desired fineness to exit the machine.

Key Components of a High-Performance Pulverizer

The reliability and efficiency of a pulverizer depend on the quality and design of its core components. Understanding these parts is essential for evaluating machine performance and maintenance needs.

- Feeding Mechanism: A well-designed feeder is crucial for consistent output. Options range from simple manual chutes to automated screw feeders for precise control.

- Grinding Chamber: This is the heavily reinforced housing where size reduction occurs. It is typically lined with hardened, abrasion-resistant plates to withstand constant impact and wear.

- Rotor Assembly: As the heart of the pulverizer, the rotor is a dynamically balanced disc or shaft fitted with grinding elements like swing hammers or fixed pins, engineered for high RPM and durability.

- Classifier/Screen: This component determines the final particle size. Perforated screens are common, while integrated air classifiers offer more precise control for producing ultra-fine powders.

- Collection System: An efficient collection system, often comprising a cyclone separator and a dust collector, ensures product is captured cleanly while maintaining a dust-free operating environment.

Types of Industrial Pulverizer Machines and Their Applications

Selecting the correct pulverizer design is critical, as different materials have unique properties that dictate the most effective grinding method. Matching the machine type to the material’s characteristics—such as hardness, moisture content, and heat sensitivity—is essential for achieving optimal results.

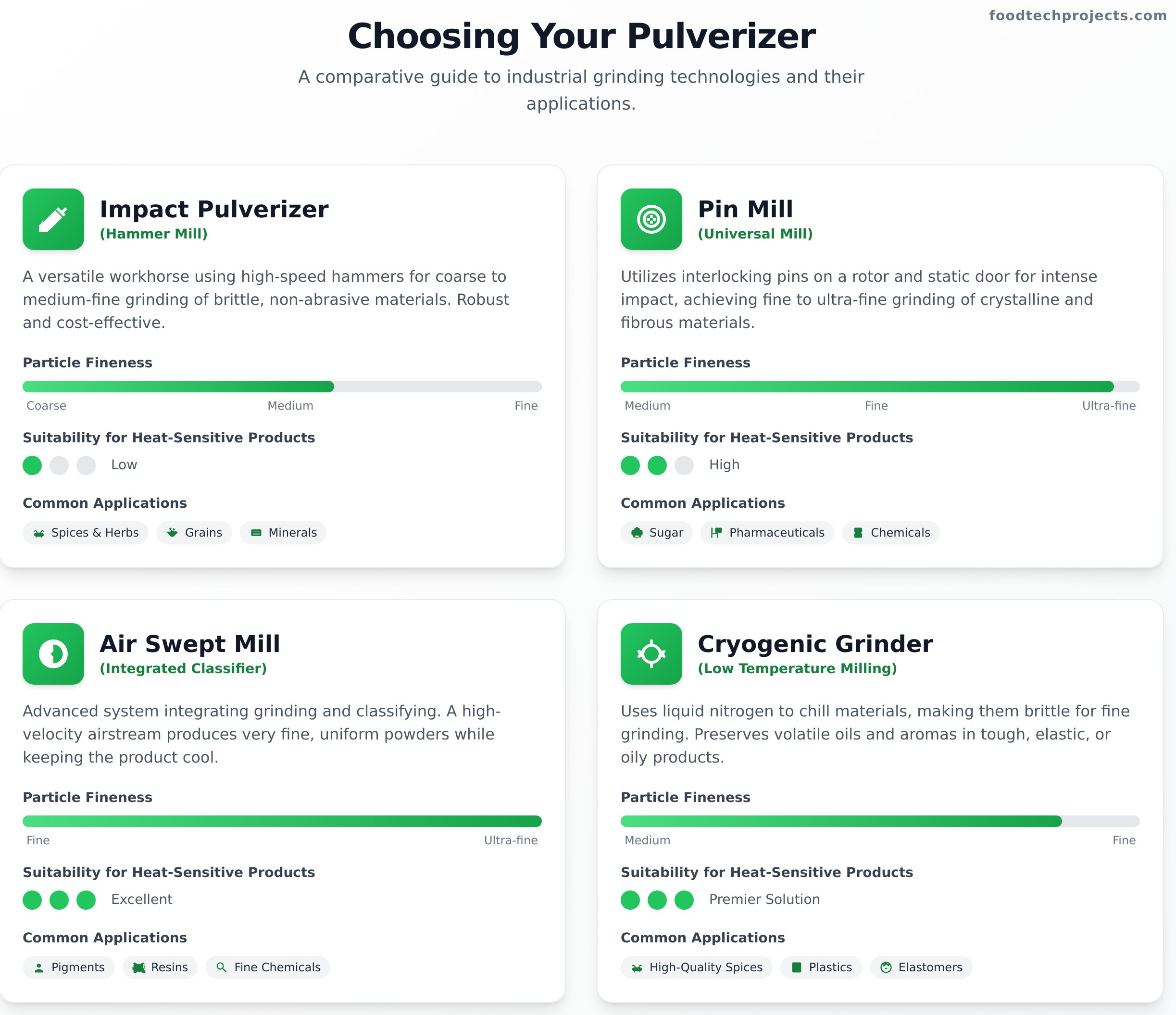

Impact Pulverizers (Hammer Mills)

Impact pulverizers, commonly known as hammer mills, are versatile workhorses ideal for coarse to medium-fine grinding of brittle, non-abrasive materials. Their robust and simple construction makes them a cost-effective solution for high-throughput operations. Common applications include the grinding of spices, grains, minerals, chemicals, and herbs.

Pin Mills (Universal Mills)

Pin mills utilize rows of interlocking pins on both a rotating disc and a static door to create intense impact and turbulence. This design is highly effective for fine and ultra-fine grinding of crystalline and fibrous materials. They are particularly suitable for heat-sensitive products due to the high air volume that passes through the mill. Key applications include sugar, pharmaceuticals, food additives, and specialty chemicals.

Air Swept Mills

Air swept mills are advanced systems that integrate grinding, classifying, and conveying into a single, efficient unit. A high-velocity airstream carries material through the grinding zone and into an internal classifier, which separates fine particles from coarse ones. This method is excellent for producing very fine, uniform powders and is ideal for heat-sensitive materials, pigments, and resins.

Cryogenic Grinders

For materials that are tough, elastic, or oily at ambient temperatures, cryogenic grinding is the premier solution. This process uses liquid nitrogen to chill the material below its embrittlement point, making it hard and friable. This allows for fine grinding without melting, degrading, or losing volatile aromas and oils. Cryogenic grinding is essential for producing high-quality ground spices, plastics, and elastomers.

How to Select the Right Pulverizer Machine: A Buyer’s Checklist

Making the right choice requires a systematic evaluation of your product, process, and production goals. A thorough analysis of your requirements will ensure you invest in a machine that delivers consistent quality, high efficiency, and a strong return on investment. Focus on your material’s specific characteristics and your desired final outcome.

Critical Selection Criteria for Optimal Performance

Before contacting a manufacturer, have a clear understanding of the following parameters. This information will allow engineers to recommend the most suitable machine for your needs.

- Material Properties: Document the material’s hardness, moisture content, oil or fat content, and abrasiveness. These factors heavily influence the type of grinding mechanism and material of construction required.

- Required Particle Size: Clearly define your target particle size, specified in mesh or microns. This is the single most important factor in determining the type of pulverizer and classifier needed.

- Production Capacity: Determine your required throughput in kilograms or tonnes per hour. This will dictate the size, motor power, and overall scale of the machine.

- Material of Construction: For food, pharmaceutical, and fine chemical applications, stainless steel (SS 304 or SS 316L) is essential to meet GMP and hygiene standards. For abrasive materials, hardened steel alloys are necessary.

- Operational Safety & Cleaning: Ensure the machine complies with safety standards and is designed for easy access and cleaning, especially if you plan to process different products on the same line.

Why Partner with Food Tech Projects for Grinding Solutions?

With over 35 years of engineering and manufacturing experience, Food Tech Projects delivers robust and efficient grinding solutions for a global clientele. We understand that every material is unique, which is why we specialize in developing customized pulverizers tailored to your specific product and process requirements. Our commitment extends beyond machine supply; we provide comprehensive turnkey project support, from initial design and consultation through to installation, commissioning, and after-sales service. Our global installation footprint and dedicated support network ensure your production line operates at peak performance. Discuss your grinding requirements with our experts.

Frequently Asked Questions (FAQs)

What is the difference between a pulverizer and a grinder?

While both are used for size reduction, a pulverizer is designed to produce a finer end product (a powder) than a typical grinder. Grinders generally produce coarser, granular particles, whereas pulverizers use higher speeds and finer screens or classifiers to achieve mesh sizes in the fine to ultra-fine range.

How do you control the final particle size in a pulverizer?

The final particle size is primarily controlled by three factors: the rotor speed, the feed rate of the material, and most importantly, the screen or classifier system. Changing the perforated screen to one with smaller or larger holes directly impacts the output size. In more advanced systems, an adjustable air classifier provides precise control for separating particles by mass.

What is the best pulverizer for grinding spices like chili and turmeric?

For spices like turmeric, which are hard and fibrous, an Impact Pulverizer or Pin Mill is highly effective. For oily and aromatic spices like chili, a Cryogenic Grinder is the ideal choice as it uses liquid nitrogen to prevent oil loss and preserve the spice’s color, flavor, and aroma during grinding.

Can a pulverizer handle heat-sensitive materials without a cooling system?

Some designs, like Pin Mills and Air Swept Mills, are inherently better for heat-sensitive materials due to the high volume of air that flows through them, providing a cooling effect. However, for extremely sensitive products, a water-cooling jacket around the grinding chamber or a fully cryogenic system is recommended to prevent degradation.

What are the maintenance requirements for an industrial pulverizer machine?

Regular maintenance includes checking for wear on the hammers, pins, and liner plates, as these are high-impact components. It is also important to inspect the screen for damage, check bearing lubrication, and ensure the collection system is clean and functioning correctly to maintain optimal performance and machine longevity.

Choosing the right industrial pulverizer is a critical decision that directly impacts your product quality and operational efficiency. By carefully evaluating your material properties, production goals, and the different technologies available, you can select a system that provides reliable performance for years to come. Partnering with an experienced manufacturer ensures you receive not just a machine, but a complete, optimized solution for your processing needs. Request a Technical Consultation for Your Pulverizer Needs to get started on engineering the perfect grinding solution for your business.