For businesses scaling up from local juice stands to commercial production, the choice of equipment is paramount. While small countertop juicers serve a purpose, industrial-scale operations require a machine for sugarcane juice engineered for high volume, efficiency, and unwavering reliability. This guide provides the essential technical knowledge for selecting a high-capacity sugarcane juice machine tailored for your food processing business, ensuring you invest in a solution that drives profitability and quality.

Beyond the Juice Stand: Understanding Industrial Sugarcane Juice Machines

The transition from a small-scale commercial juicer to an industrial extractor represents a significant leap in technology and capability. An industrial machine is not simply a larger version of its smaller counterpart; it is a purpose-built system designed for the rigors of continuous, high-volume processing. This focus on large-scale production demands superior engineering, robust materials, and precision manufacturing to handle tons of raw sugarcane per hour, maximizing juice yield while minimizing downtime.

Key Specifications for Selecting Your Machine

Evaluating an industrial sugarcane juice machine requires a focus on core technical specifications that directly impact performance and return on investment.

- Processing Capacity: The most critical metric is capacity, measured in tons per hour (TPH). Calculating your current and projected processing needs is the first step to selecting a machine that can meet demand without becoming a bottleneck in your production line.

- Juice Yield: The efficiency of juice extraction is determined by the roller design, configuration, and pressure. A high-yield machine with multiple, precision-engineered rollers maximizes the juice extracted from each stalk, directly reducing raw material waste and improving profit margins.

- Motor Power & Efficiency: The motor is the heart of the machine. Its power, measured in horsepower (HP), must be correctly matched to the machine’s processing capacity to ensure smooth, uninterrupted operation. An efficient motor also contributes to lower energy consumption.

- Construction Material: For any food processing application, the choice of material is non-negotiable. Food-grade stainless steel (SS 304 or SS 316 for higher corrosion resistance) is essential for all contact parts to ensure hygiene, durability, and compliance with international food safety standards.

Types of Industrial Sugarcane Crushers and Extractors

The industrial market offers several types of machines, each suited for different scales of operation.

- Multi-Roller Press Machines: These are the industry standard for high-efficiency extraction. Machines with three, four, or more rollers pass the sugarcane through multiple pressure points in a single pass, ensuring the highest possible juice yield.

- Crusher-Extractor Combinations: For very large-scale plants, a two-stage process involving a preliminary crusher or chopper followed by a high-pressure extractor can be employed to handle immense volumes of sugarcane effectively.

- Automation and Controls: Modern industrial lines often feature automation with integrated control panels. This allows for precise control over roller speed and pressure, automated feeding, and safety shut-offs, improving both efficiency and operator safety.

Building a Complete Sugarcane Juice Production Line

An industrial sugarcane juice machine, while critical, is just one component of a comprehensive production process. To produce a shelf-stable, marketable product, the extractor must be integrated into a complete processing line that handles every stage from raw cane intake to final packaging.

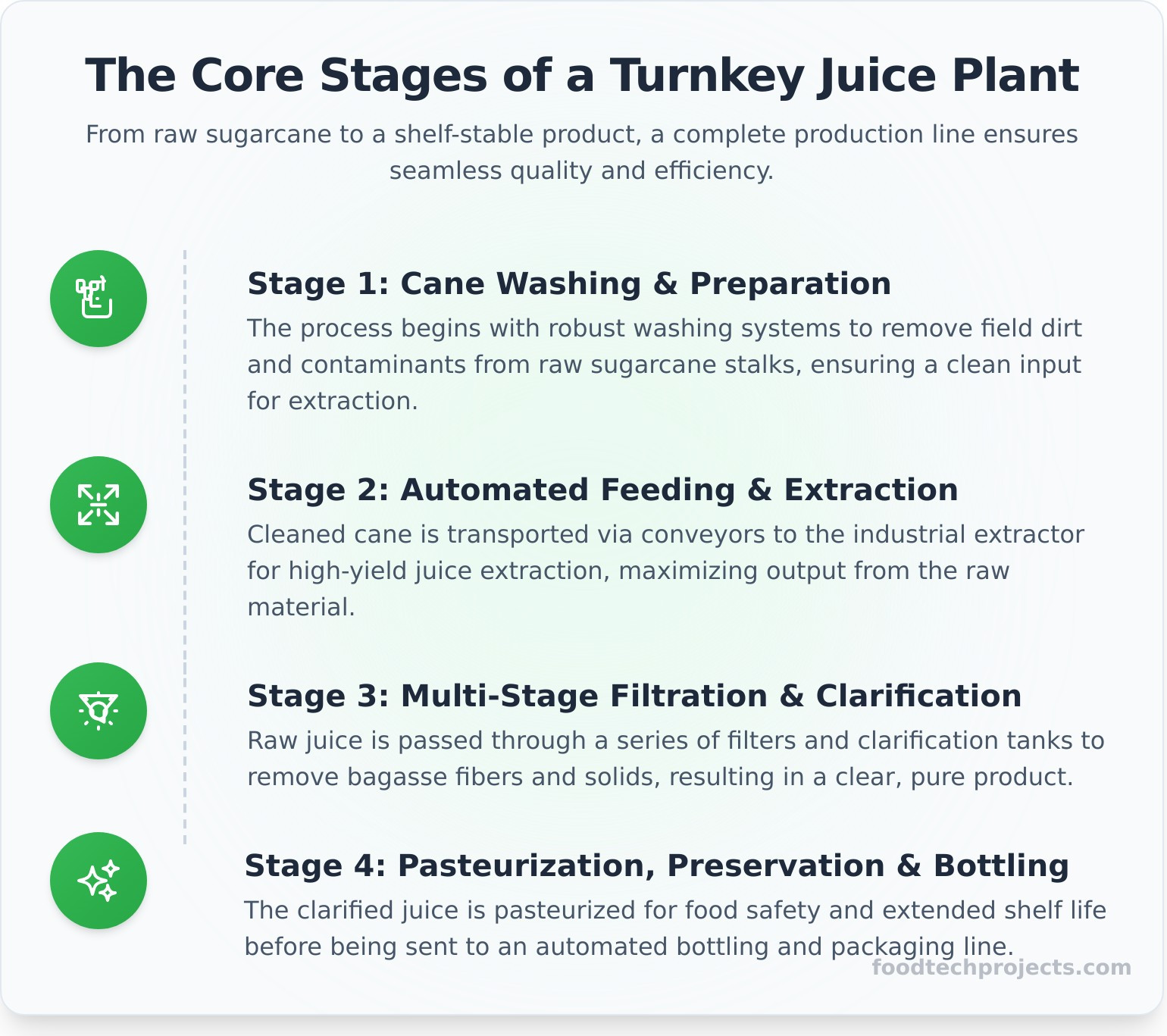

The Core Stages of a Turnkey Juice Plant

A complete turnkey plant ensures a seamless flow from start to finish, maintaining quality and hygiene throughout.

- Stage 1: Cane Washing and Preparation: The process begins with robust systems for washing and cleaning the raw sugarcane stalks to remove field dirt and contaminants.

- Stage 2: Automated Feeding and Extraction: Cleaned cane is transported via conveyors to the industrial extractor (the machine itself) for high-yield juice extraction.

- Stage 3: Multi-Stage Filtration and Clarification: The raw juice is passed through a series of filters and clarification tanks to remove bagasse fibers and other suspended solids, resulting in a clear product.

- Stage 4: Pasteurization, Preservation, and Bottling: The clarified juice is then pasteurized to ensure food safety and extend shelf life before being sent to an automated bottling and packaging line.

Why a Turnkey Solution Saves Time and Reduces Risk

Opting for a turnkey solution from a single, experienced provider offers significant advantages over sourcing individual components. A turnkey approach provides single-point responsibility for the entire project’s design, manufacturing, supply, and commissioning. This ensures all machinery components are perfectly integrated to work together seamlessly, eliminating compatibility issues. Furthermore, you gain access to invaluable expertise in factory layout design, utility planning, and adherence to international food safety compliance standards. To learn more about how a complete system can benefit your operation, discuss your turnkey plant requirements with our engineers.

Choosing Food Tech Projects for Your Sugarcane Processing Needs

With over 35 years of engineering and manufacturing experience, Food Tech Projects specializes in delivering complete, end-to-end agro-processing solutions. We understand the complexities of industrial food production and provide robust, reliable machinery designed to form the backbone of your operations.

Our Commitment to Quality and Performance

Our reputation is built on an uncompromising commitment to quality. We engineer every machine for exceptional durability and the ability to withstand the demands of continuous, 24/7 operation. Our focus on hygienic design principles ensures that our equipment is easy to clean and maintain, meeting the strictest food safety protocols. This commitment is validated by our proven track record of successful machinery installations for clients around the globe.

Global Supply Chain and Project Support

Food Tech Projects is a global leader in the export and commissioning of food processing machinery. Our experienced logistics and technical teams ensure your equipment arrives safely and is installed for optimal performance, no matter your location. We provide comprehensive after-sales service and a reliable supply of spare parts to keep your production running smoothly. We pride ourselves on being your single-window solution for all your food processing needs.

Frequently Asked Questions

What is the average juice yield from an industrial sugarcane machine?

A high-quality industrial multi-roller machine can achieve a juice yield of 65-75% of the cane’s weight, depending on the cane variety, freshness, and machine configuration.

What are the maintenance requirements for a commercial sugarcane crusher?

Routine maintenance includes daily cleaning of all food contact surfaces, regular lubrication of bearings and gears, and periodic inspection of roller pressure and condition to ensure optimal performance.

What is the difference between SS 304 and SS 316 stainless steel for food machinery?

Both are food-grade. SS 304 is the industry standard and suitable for most applications. SS 316 contains molybdenum, which provides superior resistance to corrosion from salts and acids, making it ideal for products with higher acidity or for operations in coastal areas.

Can you provide a quote for a complete sugarcane juice processing plant?

Yes. As turnkey project specialists, we can provide a detailed quotation for a complete production line, from raw material intake to final packaging, based on your specific capacity and product requirements.

What are the power and space requirements for an industrial juice extractor?

These requirements vary significantly based on the machine’s capacity (TPH). A detailed layout and utility plan will be provided as part of our project proposal, outlining the specific electrical load and floor space needed for the equipment.

Investing in the right industrial sugarcane juice machine is a foundational step toward building a successful and scalable beverage business. By focusing on robust engineering, high yield, and integration into a complete production line, you can ensure efficiency, quality, and long-term profitability. Partner with an experienced manufacturer to navigate the complexities of industrial processing and build a plant designed for success. Request a Quote for Your Industrial Sugarcane Juice Machine today to begin planning your project with our expert team.