Implementing a new agro-processing production line is a significant capital investment that demands meticulous planning and engineering expertise. For businesses aiming to transform raw agricultural products into value-added goods, the efficiency and reliability of the production line are paramount. This guide provides a comprehensive overview of turnkey agro-processing lines, covering their core components, common types, and the strategic considerations for successful project execution.

What is a Turnkey Agro Processing Production Line?

An agro-processing production line is far more than a collection of individual machines; it is a fully integrated system where each component works in a precise sequence to convert raw materials into finished, packaged products. A turnkey solution elevates this concept by placing the entire project—from initial design and engineering to equipment manufacturing, installation, and final commissioning—under the responsibility of a single, expert provider. This streamlined approach eliminates the complexities of sourcing from multiple vendors and ensures seamless integration.

The primary advantage of a turnkey model is accountability. With one partner managing the entire lifecycle, you benefit from a holistic vision that guarantees compatibility between all machines and processes. This leads directly to several key business benefits, including significantly improved operational efficiency, consistent and predictable product quality, and a faster timeline from project conception to full-scale production.

Core Stages of an Agro Processing Line: From Raw Material to Final Product

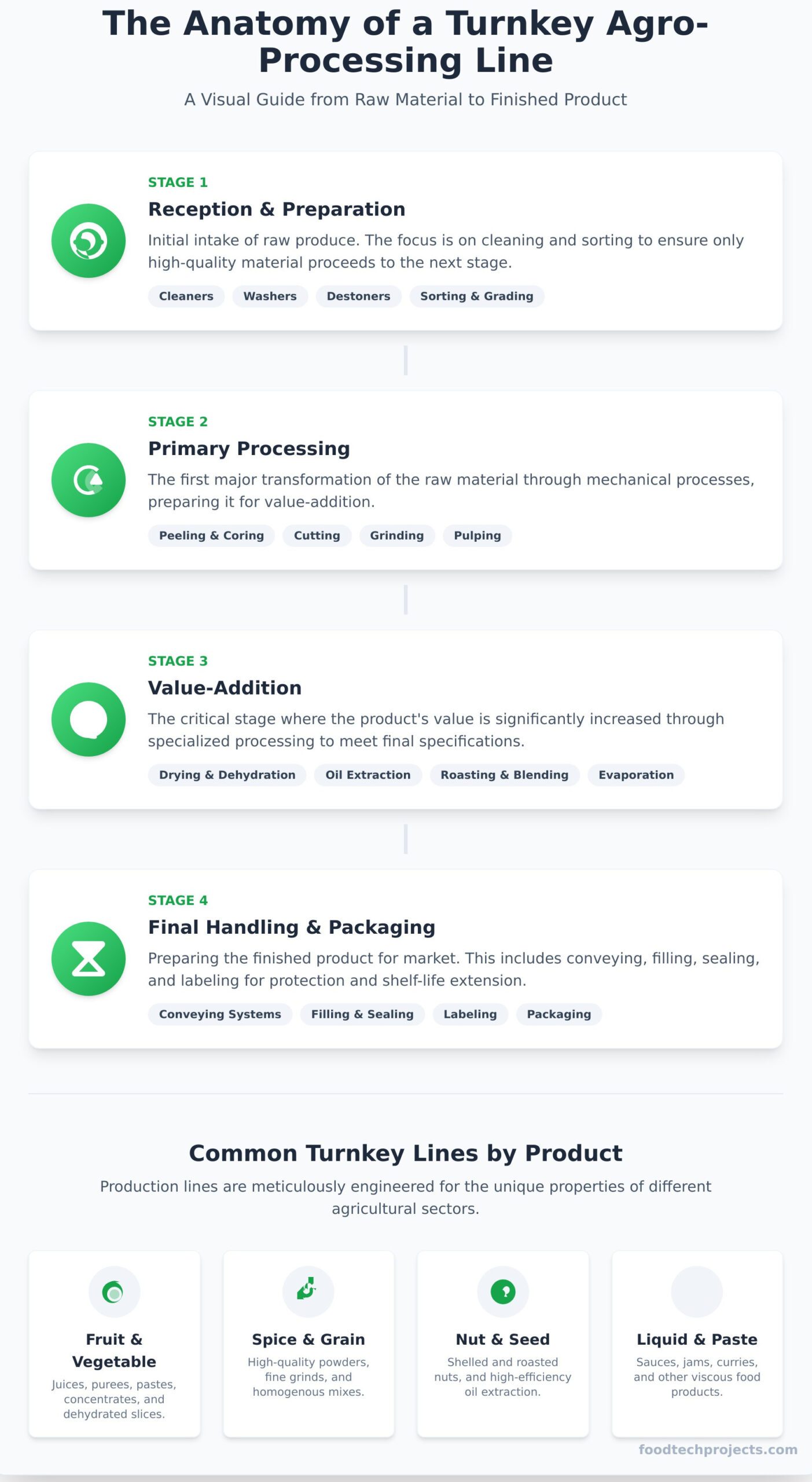

Every production line is engineered around a logical flow that systematically processes the raw material. While specifics vary based on the product, most lines include these four fundamental stages:

- Stage 1: Reception & Preparation: This initial phase involves receiving the raw agricultural produce and preparing it for processing. Key machinery includes cleaners, washers, destoners, and automated sorting and grading systems to ensure only high-quality material enters the line.

- Stage 2: Primary Processing: Here, the raw material undergoes its first major transformation. This can include mechanical processes like peeling, coring, cutting, grinding, or pulping, depending on the desired intermediate or final product.

- Stage 3: Value-Addition: This is the critical stage where the product’s value is significantly increased. Processes like industrial drying and dehydration, oil extraction, roasting, blending, or evaporation are performed using specialized equipment to achieve the final product specifications.

- Stage 4: Final Handling & Packaging: The last stage involves preparing the finished product for the market. This includes conveying systems, filling and sealing machines, labeling equipment, and final packaging solutions that protect the product and extend its shelf life.

Types of Agro Processing Lines by Product Category

Effective agro-processing production lines are not one-size-fits-all. They are meticulously engineered to handle the unique physical and chemical properties of specific raw materials. Below are common turnkey solutions designed for various major agricultural sectors.

Fruit & Vegetable Processing Lines

These lines are engineered to produce a wide range of products, including juices, purees, pastes, concentrates, and dehydrated fruit or vegetable slices. Key machines in these turnkey systems often include industrial fruit washers, pulpers, evaporators for concentration, and various types of industrial dryers to remove moisture while preserving nutrients and flavor. A complete line for producing tomato paste or mango pulp, for example, would integrate all these stages seamlessly.

Spice & Grain Processing Lines

Designed for processing dry goods, these lines focus on cleaning, grinding, and blending to create uniform, high-quality powders and mixes. Core equipment includes destoners to remove foreign particles, industrial grinders and pulverizers for fine grinding, ribbon blenders for homogenous mixing, and automated packaging units. A common application is a complete production line that transforms raw turmeric or chilies into a market-ready packaged spice powder.

Nut & Seed Processing Lines

These specialized lines are built to handle the unique challenges of processing nuts and seeds, including shelling, roasting, and oil extraction. A typical turnkey plant incorporates machinery like nut crackers or decorticators, industrial roasters for flavor development, and high-efficiency oil press machines or solvent extraction units. Turnkey cashew processing plants and coconut oil extraction facilities are prime examples of these integrated solutions.

Liquid & Paste Processing Lines

This category focuses on the blending, cooking, and packaging of liquid or semi-solid food products. Essential components include large-capacity stainless steel mixing tanks, homogenizers to ensure stable emulsions, pasteurizers for food safety, and precise filling machines for jars, bottles, or pouches. These lines are commonly used to manufacture products like sauces, jams, ready-to-eat curries, and other viscous foods.

How to Plan and Commission Your Agro Processing Line

A successful production line is the result of a strategic partnership between your business and an experienced equipment manufacturer. This collaboration is critical to ensuring the final plant is not only efficient and reliable but also provides a strong return on investment for years to come.

Key Factors in Choosing a Turnkey Solutions Provider

Selecting the right partner is the most important decision in the project. A thorough evaluation should be based on several critical factors:

- Engineering Experience: Verify the provider’s technical expertise and their historical track record in your specific industry. Case studies and client testimonials are invaluable.

- Customization & Manufacturing Capability: Ensure the provider has in-house design and manufacturing capabilities. This allows for greater quality control and the ability to customize the line to your unique requirements.

- Installation and Support: A true turnkey partner provides comprehensive on-site installation, commissioning, and staff training. Confirm they also offer robust after-sales support and spare parts availability.

- Global Project Experience: A provider with experience in executing projects globally demonstrates an understanding of diverse logistical challenges and international standards.

The Food Tech Projects Advantage: A Single Window Solution

With over 35 years of experience in food processing technology, Food Tech Projects delivers comprehensive turnkey solutions built on a foundation of engineering excellence. Our complete in-house design and manufacturing process ensures total quality control over every component of your production line. We provide a genuine “single window solution,” managing everything from concept to commissioning. Our proven track record of successful installations across the globe makes us a trusted partner for businesses looking to scale their operations with confidence. Discuss your project with our engineering team today.

Frequently Asked Questions

What is the typical cost of a complete agro-processing production line?

The cost varies significantly based on capacity, the complexity of the process, level of automation, and the specific machinery required. A small-scale line might start in the tens of thousands of dollars, while large, fully automated industrial plants can represent a multi-million dollar investment. A detailed quote is prepared after an initial engineering consultation.

How long does it take to design and install a turnkey plant?

The timeline depends on the project’s scale and complexity. Typically, it can range from 4 to 12 months. This includes the initial design and engineering phase, manufacturing of the equipment, shipping and logistics, on-site installation, and final commissioning and training.

Can you customize a production line for a niche agricultural product?

Yes. A key advantage of working with an experienced turnkey provider is the ability to custom-engineer a solution. We can design and manufacture production lines for a wide variety of niche products by adapting or creating specialized machinery to fit unique processing requirements.

Do you provide training for our staff to operate the new machinery?

Absolutely. Comprehensive on-site training for your operators and maintenance staff is a standard part of our turnkey project delivery. We ensure your team is fully competent in operating the new production line safely and efficiently before we hand over the project.

What kind of after-sales support and spare parts do you offer?

We provide robust after-sales support, including technical assistance and a reliable supply of essential spare parts to minimize downtime. Our goal is to build long-term partnerships and ensure the continued optimal performance of your plant.

Investing in a turnkey agro-processing line is a strategic move to secure efficiency, quality, and long-term profitability. By partnering with a seasoned expert like Food Tech Projects, you gain access to over 35 years of engineering experience and a proven history of global installations. We offer a true single window solution, managing every detail to deliver a production plant that meets your precise specifications. Request a Quote for Your Turnkey Food Processing Plant and take the first step toward building a world-class production facility.