For any large-scale food production enterprise, selecting the right industrial flour mill machinery is a critical investment that directly impacts product quality, operational efficiency, and profitability. Unlike domestic grain grinders designed for small-batch home use, commercial flour mill machineries are complex, integrated systems engineered for high-capacity, continuous operation. This guide will help you understand the essential components, key technologies, and crucial selection criteria to consider when investing in a flour milling plant, ensuring you can optimize your production and guarantee superior flour quality.

From Grain to Flour: The Industrial Milling Process Explained

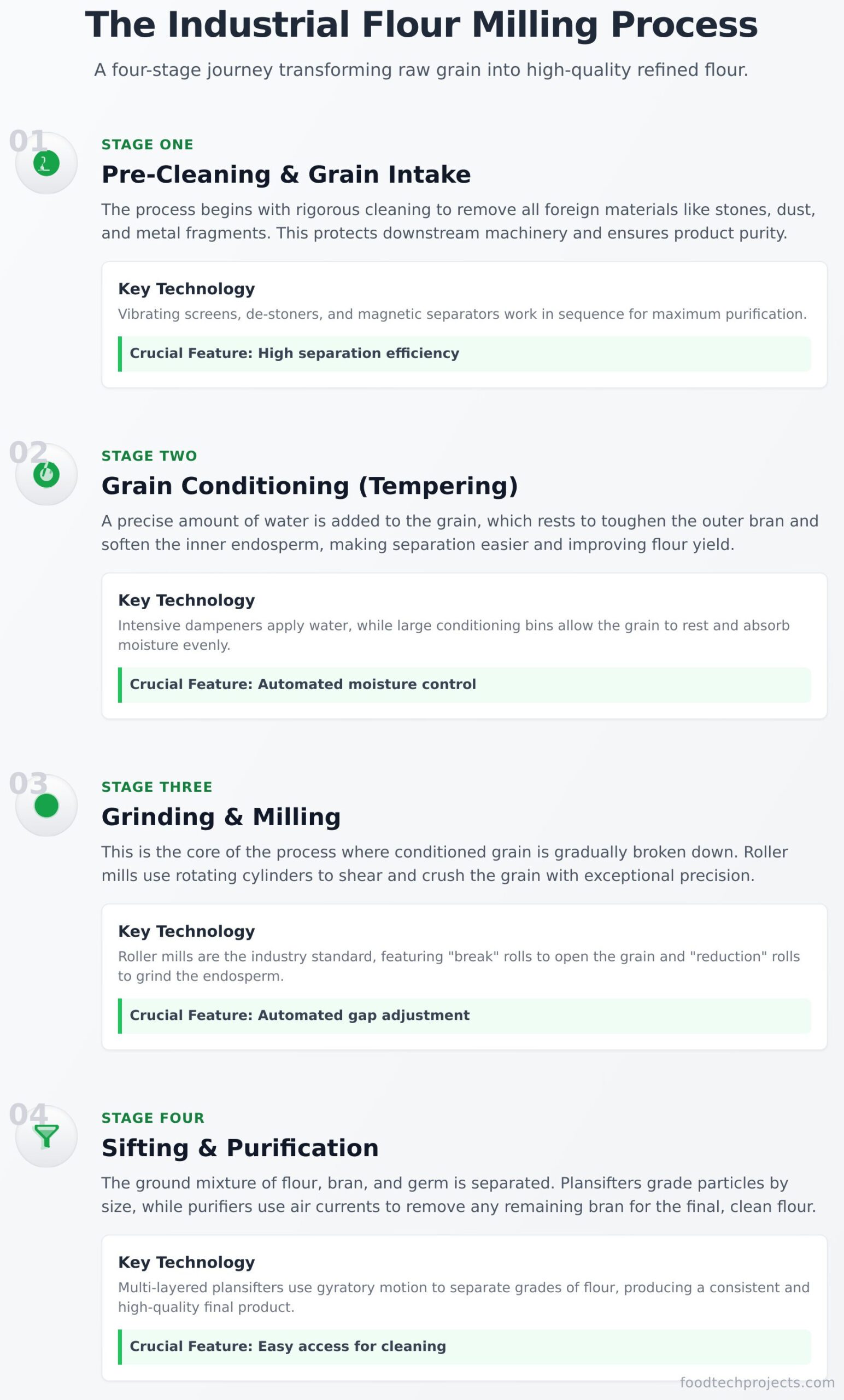

The transformation of raw grain into refined flour is a multi-stage process, where each step is performed by specialized machinery. A complete industrial production line is far more than just a grinder; it is a sophisticated system designed to clean, prepare, mill, and sort grain with precision. Understanding this process is the first step toward making an informed purchasing decision, as the performance at each stage is vital for achieving the desired yield and final product characteristics.

Stage 1: Pre-Cleaning and Grain Intake Machinery

The milling process begins with rigorous cleaning to prepare the grain for processing. The primary function of this stage is to remove all foreign materials, including stones, straw, dust, metal fragments, and other seeds. Key machines like vibrating screens, de-stoners, and powerful magnetic separators work in sequence to purify the grain. When evaluating this equipment, look for high separation efficiency to protect downstream machinery from damage and ensure the final product is free from contaminants. Durability is also paramount, as these machines are the first line of defense in the entire plant.

Stage 2: Grain Conditioning (Tempering)

After cleaning, the grain undergoes conditioning, or tempering. This critical step involves adding a precise amount of water to the grain and allowing it to rest for a specific period. The goal is to toughen the bran layer while softening the inner endosperm. This makes it easier to separate the two during milling, resulting in a cleaner flour and higher extraction rate. The machinery used includes intensive dampeners for water application and large conditioning bins for resting. The most important feature to look for here is a system that provides precise, automated moisture control, as this has a significant impact on milling performance.

Stage 3: Grinding and Milling Technology

This is the core of the flour production process, where the conditioned grain is broken down and ground into flour. The industry standard for this task is the roller mill. Unlike stone or impact mills, roller mills use a series of rotating cylindrical rolls to shear and crush the grain with exceptional control. This process is repeated through multiple passes to gradually reduce the particle size. When selecting a roller mill, pay close attention to the quality of the hardened rolls and the presence of automated gap adjustment, which ensures consistent grinding pressure and particle size.

Stage 4: Sifting and Purification

Once the grain is ground, the resulting mixture of flour, bran, and germ must be separated. This is achieved through sifting and purification. Large, multi-layered machines called plansifters use a gyratory motion to grade the particles by size, separating fine flour from coarser semolina and bran. Purifiers then use a combination of sieves and air currents to further separate any remaining bran particles from the endosperm. Key features to evaluate in this machinery include the design of the sieve stack for optimal separation and easy access for cleaning and maintenance, which is crucial for sanitation.

Anatomy of a Commercial Flour Mill: Key Components and Features

A deeper look into the core machinery reveals the advanced engineering required for modern, efficient flour production. Understanding the function of these key components will empower you to assess the quality and suitability of a potential supplier’s equipment and how it will impact your operational efficiency and the final quality of your flour.

Roller Mills: The Heart of the Operation

The roller mill is the centerpiece of any milling plant. It typically contains pairs of rolls that rotate in opposite directions at different speeds. The process is divided into stages: “break” rolls have corrugated surfaces (fluting) to shear open the grain, while “reduction” rolls are smooth to grind the endosperm into fine flour. The material of the rolls, the specific pattern of the fluting, and the surface finish are all critical to performance. Advanced models feature pneumatic controls that maintain consistent grinding pressure automatically, which is essential for uniform flour quality.

Plansifters: The Science of Separation

The plansifter is a large, enclosed box containing multiple stacks of sieves. Its complex gyratory motion causes particles to travel across the sieve surfaces, separating them based on size. This allows the mill to produce different grades of flour simultaneously. The construction of the sieve frames (traditionally wood, now often metal or composite materials) and the mesh size are crucial parameters. When evaluating a plansifter, look for a design that allows for quick and easy access to the sieve stacks, as this simplifies cleaning, inspection, and replacement, minimizing downtime.

Automation and Control Systems (PLC)

The brain of a modern flour mill is its Programmable Logic Controller (PLC) system. This centralized automation hub monitors and controls every machine in the production line, from intake to packing. The benefits are immense: it ensures consistent product quality by maintaining precise settings, reduces labor requirements, and provides valuable operational data for analysis and optimization. A key feature of a high-quality PLC system is a user-friendly interface (HMI) and the capability for remote monitoring, which allows plant managers to oversee operations and troubleshoot issues from anywhere.

How to Select the Right Flour Mill Machinery: A Buyer’s Checklist

Investing in a flour milling plant requires careful consideration of technical specifications and how they align with your business objectives. Moving beyond individual machine features to a holistic view of the entire system will help you make a sound capital investment that delivers long-term value.

Capacity and Scalability (Tons Per Day)

The first step is to define your required production capacity, typically measured in tons of grain processed per 24 hours. It is crucial to select machinery that not only meets your current business goals but also allows for future expansion. Discuss scalability options with your supplier. The chosen capacity will directly influence the physical footprint of the plant, the required utilities, and the overall project cost, so this decision must be made with a clear long-term strategy in mind.

Construction Material and Food Safety Standards

In food processing, there can be no compromise on hygiene and safety. Insist on machinery where all product-contact parts are made from food-grade stainless steel. The overall construction should be robust and heavy-duty to manage vibrations and ensure longevity. Furthermore, verify that the equipment complies with international food safety standards relevant to your target markets. This not only ensures product safety but also protects your brand’s reputation.

Energy Efficiency and Total Cost of Ownership

The initial purchase price is only one part of the equation. The total cost of ownership includes energy consumption, maintenance, and spare parts over the machine’s lifespan. Evaluate the energy efficiency of the motors used, looking for high-efficiency standards (e.g., IE3 or IE4) that can significantly reduce operational costs. A well-engineered plant will also be designed to minimize product waste and downtime, further improving your return on investment.

Partnering with a Turnkey Solutions Provider

Building a flour mill involves more than just buying machines; it requires integrating them into a cohesive, efficient system. Partnering with a turnkey solutions provider offers the significant advantage of a ‘single window solution’ for your entire project. This approach provides integrated plant design, seamless supply and installation, and unified expert support, eliminating the complexity of coordinating multiple vendors. At Food Tech Projects, we specialize in providing end-to-end engineering for complete flour milling plants, from initial concept to final commissioning. If you are considering a new project, we invite you to Request a consultation for your turnkey flour mill project.

Frequently Asked Questions

What is the difference between a roller mill and a stone mill in commercial use?

In commercial production, roller mills are the standard because they offer precise control over particle size, higher extraction rates, and better separation of bran and germ. Stone mills grind the entire grain kernel together, producing whole-grain flour, but are less suitable for producing the refined white flours required by the mass market.

How much power is required to run an industrial flour mill plant?

Power requirements vary significantly based on the plant’s capacity (tons per day). A small-scale plant might require 50-100 kW, while a large-capacity mill could require over 1000 kW. A detailed power assessment is a core part of the plant design process.

What are the main factors affecting the final quality of the flour?

The three main factors are: the quality of the raw grain, the precision and quality of the milling machinery, and the skill of the miller or plant operator in managing the process and settings.

How often does flour mill machinery require maintenance?

A preventive maintenance schedule is crucial. Daily checks, weekly cleaning, and monthly inspections of key components like rolls and sieves are standard. Major overhauls or roll re-fluting might be required annually or biannually, depending on usage.

Can you process different types of grains (like wheat, maize, rice) with the same machinery?

While some core machines like cleaners and conveyors are versatile, the milling section (roller mills, sifters) is typically optimized for a specific grain. Milling maize (corn) or rice requires different roll configurations and process flows compared to wheat. A multi-grain plant would require specialized or additional equipment.

Choosing the right flour mill machinery is a foundational decision for your business. By focusing on the entire process, understanding the key technologies, and prioritizing quality, efficiency, and safety, you can build a productive and profitable operation. A partnership with an experienced turnkey provider can de-risk this complex process and ensure your plant is engineered for success from day one. Design Your Complete Flour Milling Plant with Our Experts and leverage over 35 years of global experience in food processing technology.