Selecting the optimal industrial dryer or dehydrator is a critical decision that directly impacts product quality, operational efficiency, and profitability. For food processors, understanding the core technologies behind moisture removal is the first step toward making a sound investment. This comprehensive guide provides the essential knowledge needed to navigate the complexities of industrial drying, from fundamental principles to selecting the right machinery for your specific application.

Fundamentals of Industrial Dehydration Technology

At its core, industrial dehydration is the process of removing moisture from a food product to inhibit the growth of microorganisms and prevent spoilage. This preservation technique offers several key benefits crucial for the modern food industry: it dramatically extends shelf life, reduces product weight and volume for easier storage and transport, and, when done correctly, preserves the vital nutrients, colors, and flavors of the original material. The process relies on three core principles of heat transfer to effectively remove water content.

- Convection: The most common method, where heated air is circulated over the product to carry moisture away.

- Conduction: Heat is transferred through direct contact with a heated surface.

- Radiation: Heat is transferred via electromagnetic waves, such as infrared or microwaves.

Key Parameters That Determine Drying Success

Achieving a perfectly dried product requires precise control over several environmental factors. Mastering these parameters ensures consistent quality, maximizes throughput, and minimizes energy consumption.

- Temperature: The primary driver of drying speed. It’s a delicate balance; higher temperatures dry faster but can damage heat-sensitive nutrients, flavors, and colors. The ideal temperature is specific to each product.

- Airflow: The volume and velocity of air moving over the product are critical for efficiently carrying away evaporated moisture. Proper airflow prevents saturation at the product’s surface, accelerating the drying process.

- Humidity: The relative humidity of the drying air must be carefully controlled. Low-humidity air can absorb more moisture, but excessively dry air can cause “case hardening,” where the outside of the product dries too quickly, trapping moisture inside.

- Drying Time: The total time required to reach the target moisture content. This is influenced by all the above factors, as well as the product’s size, shape, and initial moisture level. Optimizing drying time is key to maximizing production throughput.

Types of Industrial Dryers and Dehydrators

Industrial dryers are not a one-size-fits-all solution. They are highly specialized machines, primarily categorized by their method of heat transfer and material handling. Each type is engineered to process different food products and accommodate various production scales, from small batches to continuous, high-volume lines.

Convection Dryers (Hot Air)

These are the workhorses of the food industry, utilizing heated air to remove moisture. They are versatile and effective for a wide range of products, including fruits, vegetables, spices, and meats.

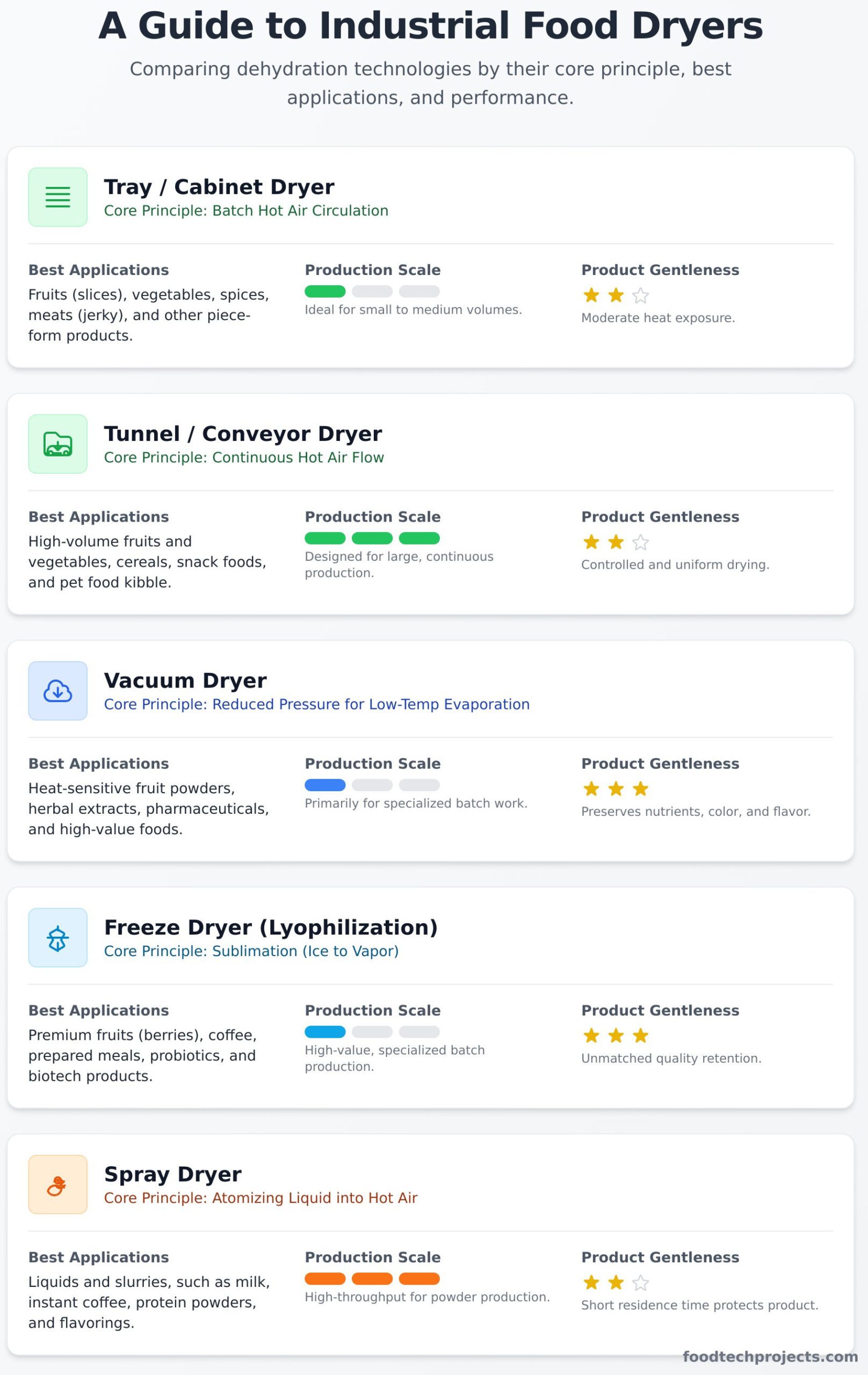

- Tray/Cabinet Dryers: Ideal for batch processing and suitable for smaller to medium production volumes. Product is loaded onto trays, which are then placed inside an insulated cabinet where hot air is circulated.

- Tunnel/Conveyor Dryers: Designed for continuous, large-scale production. The product moves through a long tunnel on a conveyor belt while being exposed to a controlled flow of hot air, ensuring uniform drying.

- Fluid Bed Dryers: Best for drying powders, grains, and granulated materials. A stream of hot air is passed up through the product bed, causing it to behave like a fluid, which allows for extremely efficient and rapid drying.

Conduction and Vacuum Dryers

These systems rely on direct contact with a heated surface to transfer energy.

- Vacuum Dryers: By reducing the ambient pressure, these dryers lower the boiling point of water, allowing for low-temperature drying of extremely heat-sensitive products. This method is excellent for preserving the color, flavor, and delicate nutritional compounds of high-value foods, pharmaceuticals, and extracts.

Advanced Dehydration Systems

For specialized applications, advanced technologies offer unique benefits.

- Freeze Dryers (Lyophilization): This process involves freezing the product and then reducing the pressure to allow the frozen water to sublimate directly from a solid to a gas. It yields a premium-quality product with an exceptionally long shelf life and excellent rehydration properties.

- Spray Dryers: This technology is used to convert liquids, slurries, and low-viscosity pastes into dry powders. The liquid is atomized into a hot air stream, causing rapid evaporation and forming a fine powder.

- Flash Dryers: Designed for the rapid drying of materials like pastes and filter cakes that have a relatively high moisture content. The material is dispersed into a hot gas stream for very short residence times.

How to Choose the Right Industrial Dryer for Your Application

Selecting the right industrial dryer is a critical capital investment that directly impacts your return on investment and final product quality. A methodical, step-by-step approach is essential to ensure you choose a machine that aligns perfectly with your production needs and product characteristics.

Step 1: Analyze Your Product’s Characteristics

The nature of your raw material is the most important factor in determining the appropriate drying technology. Consider its physical form—whether it’s a solid, liquid, powder, or paste. Evaluate its heat sensitivity; can it withstand high temperatures without degrading? Finally, define your moisture content targets, from the initial state to the final desired level.

| Dryer Type | Best Food Applications |

|---|---|

| Tray/Cabinet Dryer | Fruits (slices, pieces), Vegetables, Spices, Meats (jerky) |

| Tunnel/Conveyor Dryer | High-volume Fruits and Vegetables, Cereals, Pet Food |

| Vacuum Dryer | Heat-sensitive Fruit Powders, Herbal Extracts, Pharmaceuticals |

| Freeze Dryer | High-value Fruits (berries), Coffee, Prepared Meals, Probiotics |

| Spray Dryer | Milk, Whey, Eggs, Instant Coffee, Food Flavorings (liquids) |

Step 2: Evaluate Key Technical Specifications

Once you’ve shortlisted dryer types, dive into the technical details to compare specific models.

- Capacity and Throughput: Ensure the machine’s processing capacity (e.g., kg/hour) aligns with your current and future production goals.

- Energy Efficiency: Compare the energy consumption and heat source (gas, electric, steam) to understand the long-term operational costs.

- Material of Construction: For food applications, verify that all contact parts are made from food-grade stainless steel (such as SS304 or SS316) to ensure hygiene and durability.

- Control Systems: Modern PLC (Programmable Logic Controller) automation provides precise control over temperature, airflow, and drying time, ensuring consistent product quality and reducing manual oversight.

Step 3: Selecting a Manufacturer and Partner

Your relationship with the manufacturer is as important as the machine itself. A reliable partner provides more than just equipment; they offer expertise and support.

- Look for a manufacturer with a proven track record and extensive experience in your specific sector of the food industry.

- Inquire if they offer testing facilities to run trials with your specific product, which can validate the technology before purchase.

- Prioritize suppliers who offer comprehensive turnkey solutions, managing everything from initial design and engineering to installation and commissioning.

- For long-term reliability, verify the availability of global support, ongoing service, and a ready supply of spare parts. If you are looking for a partner that can manage your entire process, Request a consultation on your turnkey project.

Frequently Asked Questions

What is the difference between a dryer and a dehydrator in an industrial context?

In the industrial food processing industry, the terms “dryer” and “dehydrator” are often used interchangeably. Both refer to machinery designed to remove moisture from a product. “Dryer” is a broader engineering term, while “dehydrator” is more commonly used in the context of food preservation.

How does industrial dehydration affect the nutritional value of food?

The effect on nutritional value depends heavily on the drying method and temperature. Low-temperature methods like vacuum drying and freeze-drying are excellent at preserving heat-sensitive vitamins (like Vitamin C) and antioxidants. While some nutrient loss is inevitable with any heat processing, modern industrial dryers are designed to minimize this degradation through precise control.

What are the average energy costs of running an industrial dryer?

Energy costs vary significantly based on the dryer’s size, technology, heat source (natural gas is often cheaper than electricity), and local utility rates. Modern, well-insulated dryers with heat recovery systems are significantly more efficient. Manufacturers should be able to provide estimated energy consumption figures (e.g., kWh per kg of water evaporated) for their equipment.

What maintenance is required for industrial food dehydrators?

Routine maintenance typically includes regular cleaning to ensure food safety, inspection of moving parts like belts and fans, lubrication of motors and bearings, and calibration of sensors and controls. A good manufacturer will provide a detailed maintenance schedule and support plan.

Can you test my specific product before I make a purchase?

Reputable and experienced manufacturers often have pilot plants or testing facilities where you can run trials with your own product. This is a crucial step to verify the machine’s performance and confirm that the final product quality meets your standards before committing to a large capital expenditure.

How long does it take to manufacture and install a dryer system?

Lead times depend on the complexity and size of the machine. A standard cabinet dryer may take a few weeks, while a large, custom-designed turnkey tunnel dryer line can take several months to manufacture, ship, install, and commission. It’s essential to discuss timelines with the manufacturer early in the planning process.

Choosing the right industrial drying equipment is a foundational step in building a successful food processing operation. By understanding the core technologies, analyzing your product needs, and partnering with an experienced manufacturer, you can implement a solution that ensures high-quality output and long-term profitability. With over 35 years of experience delivering turnkey project solutions to clients in more than 25 countries, our team has the expertise to guide you through every stage. Discuss your project with our engineers for a custom solution.