Selecting the right flour mill machine is a critical decision for any commercial food processing operation. Unlike domestic grinders designed for small-batch home use, industrial mills are engineered for high-volume, continuous production, demanding precision, durability, and efficiency. This guide provides a technical overview of industrial flour mill machines, covering their core components, types, and key specifications to help you make an informed investment for your production line.

Understanding Industrial Flour Mill Machines vs. Domestic Grinders

An industrial flour mill machine is a core production asset engineered to grind grains, spices, and other raw materials into powders of a specified fineness at a commercial scale. The primary distinction lies in their design and purpose. While a domestic grinder is built for intermittent use, an industrial machine is constructed for continuous, 24/7 operation, featuring robust components and powerful motors. Key differences include capacity, durability, and the precision of the final grind, which are paramount in a commercial setting.

Core Components of a Commercial Milling Machine

Understanding the fundamental components of an industrial mill is essential for evaluating its performance and suitability for your application. A typical machine consists of four primary systems:

- Feeding Mechanism: This includes the hopper and input controls that regulate the flow of raw material into the grinding chamber, ensuring a consistent and manageable feed rate for optimal performance.

- Grinding Chamber: As the heart of the machine, this is where the size reduction occurs. The design of this chamber and its internal components (e.g., rollers, hammers, pins) determines the machine’s grinding principle and application.

- Drive System: Comprising the motor, belts, and power transmission components, the drive system provides the necessary power and rotational speed for the grinding mechanism to function effectively.

- Collection System: After grinding, the powdered material is discharged and collected. This often involves cyclones, filters, and discharge outlets designed to handle high volumes of product efficiently and with minimal dust.

The Role of Flour Mills in a Turnkey Production Line

In a large-scale food processing plant, milling is rarely a standalone operation. It is a crucial step integrated within a larger, comprehensive production line. For maximum efficiency, the flour mill must work in synergy with upstream equipment like pre-cleaners and de-stoners, as well as downstream systems such as sifters, mixers, and packaging machines. Adopting a “single window solution” where the entire line is designed by one expert provider ensures seamless integration and eliminates bottlenecks. If you are planning a complete production facility, consult our experts on turnkey plant design.

Types of Industrial Flour Mill Machines and Their Applications

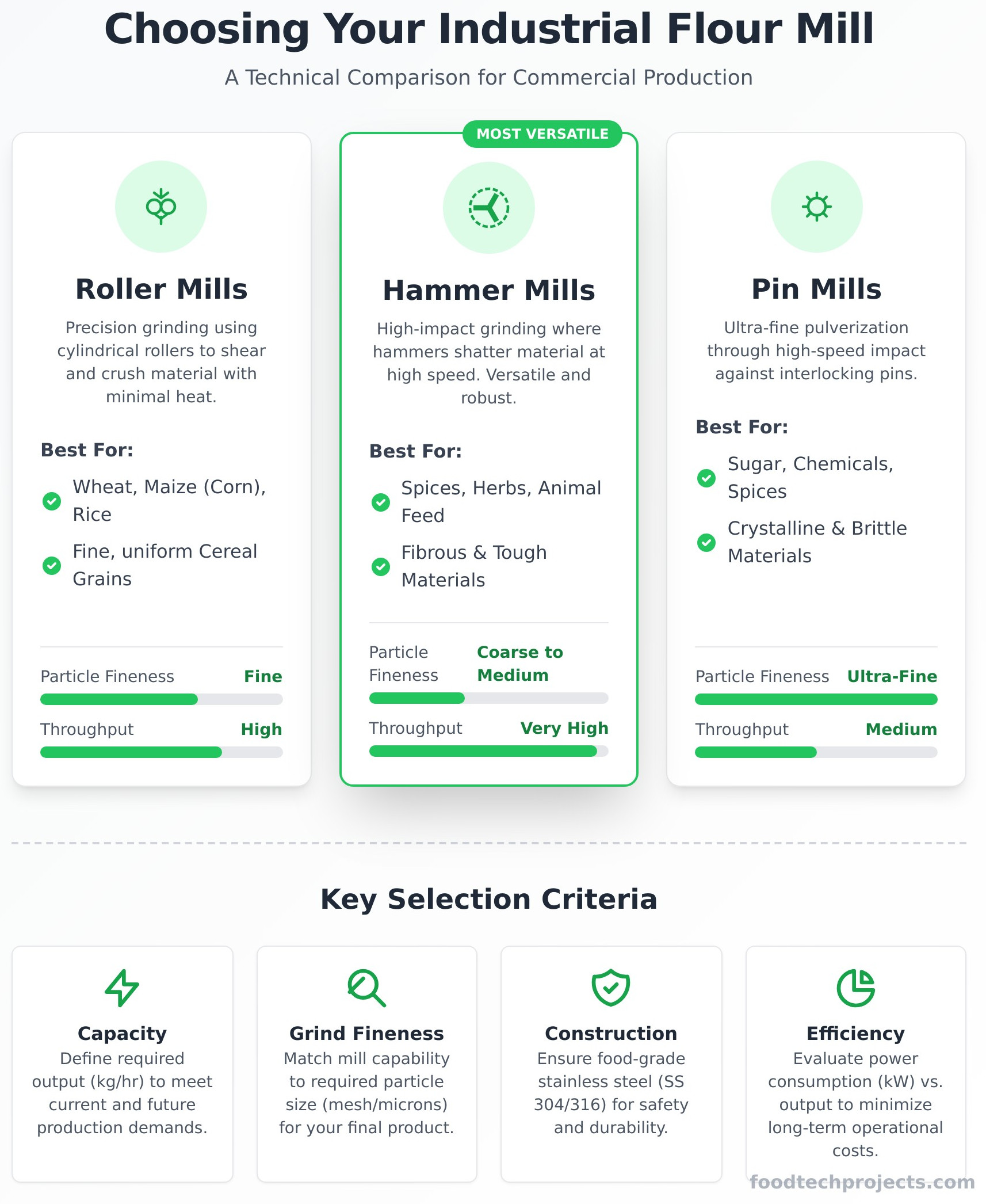

Choosing the correct milling technology is critical and depends entirely on your raw material and desired end-product characteristics. Each type of industrial mill utilizes a different mechanical principle to achieve size reduction, offering unique advantages for specific applications.

Roller Mills: Precision Grinding for Grains

Roller mills use a series of cylindrical rollers, often rotating at different speeds, to shear and crush material as it passes through the gap between them. This method provides excellent control over particle size and generates minimal heat, which is vital for preserving the quality of heat-sensitive products like wheat flour.

- Best for: Wheat, maize (corn), rice, and other cereal grains where a fine, uniform flour is the primary objective.

- Advantages: Produces highly uniform particle size, offers excellent control, and its low-heat operation protects nutrient and protein quality.

Hammer Mills: High-Impact Grinding for Diverse Materials

A hammer mill operates on the principle of impact. A high-speed rotating shaft fitted with multiple hammers shatters the material upon collision inside the grinding chamber. The final particle size is determined by a screen that allows material to pass through only once it is small enough.

- Best for: A wide range of materials including spices, herbs, coarse grains, biomass, and animal feed. They excel where high throughput is more critical than perfect uniformity.

- Advantages: Extremely robust and versatile, capable of handling fibrous or tough materials, and offers a very high production capacity.

Pin Mills (Universal Mills): Ultra-Fine Pulverization

Pin mills, also known as universal mills, achieve ultra-fine grinding through the impact of material against rows of interlocking pins on both a rotating and a stationary disc. The intense, high-speed impact results in extremely fine powders, often measured in low micron sizes.

- Best for: Crystalline materials like sugar, chemicals, and certain spices where an ultra-fine, almost talc-like powder is required.

- Advantages: Capable of achieving extremely fine particle sizes (superfine powders) that other mills cannot produce.

Key Specifications for Selecting a Flour Mill Machine

When investing in industrial machinery, it is crucial to look beyond the initial price and evaluate the technical specifications that will determine its performance, efficiency, and return on investment. Matching the machine’s capabilities to your specific production goals is essential for long-term success.

Capacity and Throughput (kg/hr or tons/day)

The first step is to clearly define your required production output. This specification indicates how much raw material the machine can process in a given period. It is wise to consider not only your current needs but also future scalability to accommodate business growth. The mill’s throughput must be balanced with your upstream and downstream equipment to prevent operational bottlenecks.

Fineness of Grind (Mesh Size or Microns)

The required final particle size of your product is a critical factor. This is often measured in mesh size (number of openings per linear inch of a screen) or microns. The fineness of the powder impacts its texture, solubility, and suitability for its final application. The machine’s design, along with the screens or classifiers used, will determine its ability to achieve your desired fineness consistently.

Material of Construction and Durability

For any food processing application, the material of construction is non-negotiable. Food-grade stainless steel (typically SS 304 or SS 316 for corrosive materials) is essential to prevent contamination and comply with food safety standards. Look for heavy-duty construction and high-quality components that can withstand the rigors of continuous, demanding operation, ensuring machine longevity and reliability.

Power Consumption and Operational Efficiency

The machine’s motor power (measured in HP or kW) should be evaluated relative to its production output. An efficient design minimizes energy consumption per unit of product, which significantly reduces long-term operating costs. Features that reduce material waste, simplify cleaning, and minimize downtime for maintenance also contribute to overall operational efficiency. To properly evaluate our machinery, we encourage you to request a technical specification sheet for our models.

Frequently Asked Questions (FAQs)

What is the difference between a flour mill and a pulverizer?

While the terms are often used interchangeably, “flour mill” typically refers to machines designed for grinding grains into flour (like roller mills). A “pulverizer” is a more general term for any machine that grinds material into fine powder and often refers to impact-based machines like hammer mills or pin mills used for a wider variety of materials, including spices and chemicals.

How much does an industrial flour mill machine cost?

The cost varies significantly based on capacity, type, material of construction, and motor power. Small commercial mills may start from a few thousand dollars, while large-scale industrial systems for full production plants can represent a substantial capital investment. It is best to request a quote based on your specific requirements.

What maintenance is required for a commercial flour mill?

Regular maintenance includes checking and tightening belts, lubricating bearings, inspecting grinding components (hammers, rollers, pins) for wear, and cleaning the machine thoroughly to prevent cross-contamination. Adhering to the manufacturer’s recommended maintenance schedule is crucial for ensuring longevity and optimal performance.

Can one machine be used to grind different types of grains?

Some machines, particularly hammer mills, are versatile and can process a variety of materials with adjustments to screens and rotor speed. However, for optimal results and to avoid cross-contamination (especially with allergens like gluten), dedicated machines are often recommended for different product types in a commercial setting.

How do I choose the right motor power (HP) for my flour mill?

The required motor power depends on the hardness of the raw material, the desired throughput, and the target fineness. Harder materials and finer grinds require more power. A manufacturer can help you calculate the appropriate motor size based on your specific application to ensure efficiency without being underpowered.

What is the typical lifespan of an industrial-grade flour mill?

With proper maintenance and operation, a well-built industrial flour mill machine from a reputable manufacturer can last for decades. The lifespan is primarily determined by the quality of construction, the materials used, and the diligence of the maintenance program.

Choosing the right industrial flour mill is a foundational step in building an efficient and profitable food processing operation. By understanding the core technologies and evaluating key specifications, you can select a machine that delivers consistent quality and reliable performance. With over 35 years of experience in manufacturing and deploying turnkey food processing solutions globally, Food Tech Projects is your trusted partner. Request a Quote for Your Industrial Milling Needs today and let our engineers design the perfect solution for your business.