In the world of large-scale food production, efficient and reliable storage is not a luxury—it is the foundation of a profitable operation. Grain storage silos are more than just containers; they are sophisticated engineering systems designed to protect valuable commodities, maintain quality, and ensure the seamless flow of materials through a processing facility. This guide provides a comprehensive overview of the critical engineering principles, types, and integrated systems of grain silos, enabling project planners and plant managers to make informed decisions for their storage and processing needs.

What is a Grain Silo and Its Strategic Role in Food Processing?

A grain silo is a specialized, engineered structure designed for the bulk storage of granular materials, primarily grains like wheat, corn, rice, and barley. Its core purpose is to protect these commodities from environmental factors and facilitate efficient handling, forming a critical link between harvest or delivery and the subsequent processing stages. In the context of a complete production facility, the silo acts as a strategic buffer, ensuring that the processing line has a consistent and reliable supply of raw materials, thereby maximizing operational uptime and efficiency. It is an indispensable component in any modern turnkey food processing plant.

Core Functions: Beyond Simple Storage

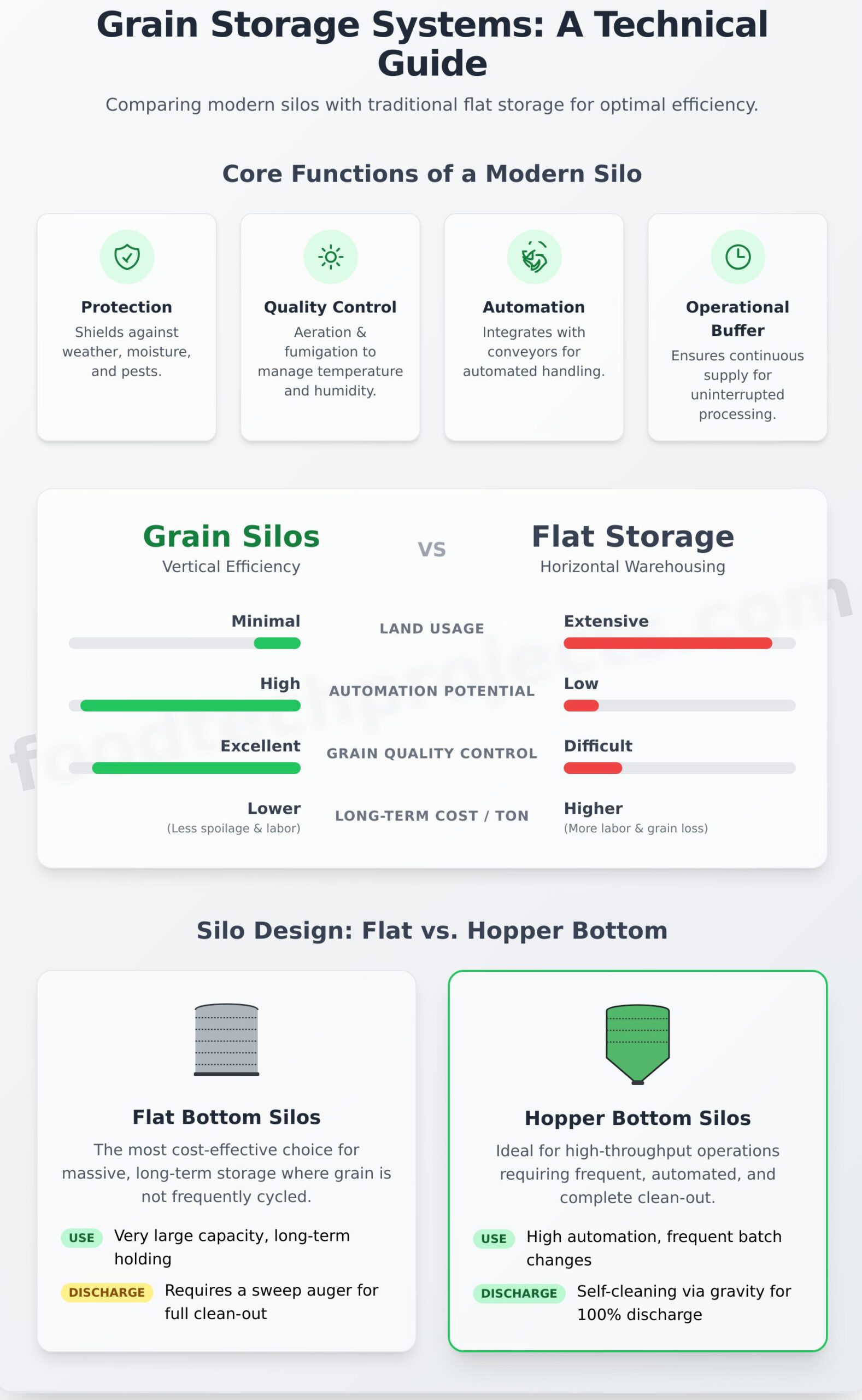

While containment is their most visible function, modern silos perform several active roles essential for preserving the value of stored grain. These advanced capabilities are what truly set them apart from basic warehousing.

- Protection: Silos provide a robust shield against weather, moisture, and pests. Their sealed design prevents contamination and spoilage that can lead to significant financial losses.

- Quality Preservation: Integrated systems for controlled aeration and fumigation are vital. These allow operators to manage temperature and humidity levels, preventing mold growth and insect infestation, thus preserving the grain’s quality and grade.

- Automation: Silos are designed to integrate with material handling equipment like bucket elevators and conveyors, enabling automated loading and unloading processes. This reduces labor costs and improves operational speed and safety.

- Operational Buffer: By holding a substantial reserve of raw materials, silos decouple the plant’s production schedule from the logistics of grain delivery, ensuring a continuous and uninterrupted manufacturing process.

Grain Silos vs. Flat Storage: A Technical Comparison

Choosing between vertical silos and horizontal flat storage (warehouses) is a critical decision based on operational priorities. While flat storage may seem simpler, silos offer significant technical and efficiency advantages for most industrial applications.

| Factor | Grain Silos | Flat Storage (Warehouse) |

|---|---|---|

| Land Usage | Minimal footprint; builds vertically to maximize capacity on limited land. | Requires a large horizontal area for equivalent capacity. |

| Automation Potential | High. Easily integrates with automated loading, unloading, and monitoring systems. | Low. Relies heavily on manual labor and equipment like loaders for handling. |

| Grain Quality Control | Excellent. Sealed environment with precise aeration and fumigation capabilities. | Difficult. Large surface area makes it hard to control temperature and pests. |

| Cost Per Ton | Lower long-term operational cost due to automation and reduced spoilage. | Higher long-term operational cost due to labor and potential for grain loss. |

Fundamental Engineering Principles in Silo Design

The specification of a grain silo is a complex engineering task that balances capacity, material science, and operational requirements. The final design is carefully tailored to the specific type of grain being stored, the local climate, and the required throughput of the processing facility. Understanding these core principles is essential for selecting the right storage solution.

Structural Design: Flat Bottom vs. Hopper Bottom Silos

The most fundamental design choice is the shape of the silo’s base, which directly impacts how grain is discharged. A flat bottom silo rests on a concrete slab, while a hopper bottom silo features a sloped, cone-shaped base that funnels grain to a central discharge point.

- Flat Bottom Silos: These are the most cost-effective solution for very large capacity, long-term storage where the grain is not frequently cycled. Discharge requires a sweep auger to clean out the remaining grain after gravity has emptied the central portion.

- Hopper Bottom Silos: Also known as self-cleaning silos, these are ideal for applications requiring frequent, complete clean-out and high levels of automation. The conical bottom ensures that all grain is discharged via gravity, eliminating the need for manual intervention and reducing the risk of cross-contamination between batches. The choice is ultimately dictated by the facility’s discharge requirements and operational philosophy.

Materials of Construction: Steel, Concrete, and Composites

The material used to construct the silo determines its durability, cost, and suitability for different applications. Each has distinct advantages.

- Galvanized Steel: Corrugated galvanized steel is the industry standard for most grain silo construction. It offers an excellent balance of strength, longevity, and cost-effectiveness, providing robust protection against corrosion.

- Stainless Steel: For specific food-grade applications or highly corrosive materials, stainless steel is the preferred choice, offering superior hygiene and resistance to degradation.

- Concrete: Poured-in-place or precast concrete silos are used for massive capacity requirements and are known for their extreme longevity and thermal mass, which helps moderate internal temperature fluctuations.

Calculating Load and Capacity Requirements

Proper structural engineering is paramount to silo safety and integrity. Engineers must account for numerous forces, starting with the properties of the stored grain itself, such as its bulk density and angle of repose. Calculations must consider both the static load of the grain at rest and the dynamic loads exerted during the filling and discharging processes. Furthermore, the design must incorporate environmental factors, including regional wind, snow, and seismic loads, to ensure the structure remains sound under all conditions.

Key Systems for Maintaining Grain Quality in Silos

A modern silo is an active system, not merely a passive container. Its value is maximized through the integration of key subsystems designed to monitor and maintain the quality of the stored commodity. These systems are a crucial investment to prevent spoilage, which can result in catastrophic financial loss.

Aeration and Ventilation Systems

The primary purpose of an aeration system is to control the temperature and moisture content of the grain mass. By using fans to push ambient or chilled air through perforated floors and up through the grain, operators can equalize temperatures, prevent moisture migration, and remove heat generated by respiration. This proactive management is the single most effective method for preventing mold growth, inhibiting insect infestation, and avoiding heat damage.

Temperature and Moisture Monitoring

To effectively manage aeration, operators need accurate data from within the silo. This is achieved with temperature and moisture monitoring systems, which consist of sensor cables suspended vertically within the grain. These sensors provide real-time readings at multiple points, allowing operators to detect the formation of hotspots or areas of high moisture. This early warning system enables proactive intervention and is essential for modern quality management protocols.

Integrated Material Handling Equipment

A silo cannot function in isolation; it must be connected to the facility’s broader material flow. This requires a suite of integrated handling equipment. Bucket elevators are typically used for the vertical transport required for loading the silo from the top, while screw conveyors or chain conveyors are used for unloading from the bottom and transporting grain to the next processing stage. Designing these systems correctly ensures a reliable, automated flow of materials and connects the silo seamlessly into the rest of the production line. To see how these components fit together, you can explore our turnkey grain processing solutions.

Frequently Asked Questions

What is the primary difference between a grain bin and a grain silo?

In the industry, the terms are often used interchangeably. However, “silo” typically refers to taller, more slender structures used for commercial or industrial-scale storage, while “bin” may refer to smaller, wider structures often found on farms.

How do you calculate the storage capacity of a grain silo?

The capacity is calculated based on the silo’s volume (using the formula for a cylinder and, if applicable, a cone for the hopper). This volume is then multiplied by the bulk density of the specific grain being stored to determine the total tonnage or bushels.

What are the most important safety precautions for operating grain silos?

The most critical safety rule is to never enter a silo when grain is flowing and to always follow strict lock-out/tag-out procedures for all powered equipment. Other precautions include monitoring for dust accumulation to prevent explosions and ensuring proper ventilation.

How long does a galvanized steel grain silo typically last?

With proper maintenance and in a typical environment, a high-quality galvanized steel silo can have a service life of 25 to 40 years or more. Longevity depends on factors like the quality of the galvanization, climate, and the type of material stored.

Is a flat bottom or hopper bottom silo better for my application?

If you require large-volume, long-term storage with infrequent discharge, a flat bottom silo is more economical. If your process requires frequent, complete clean-out, batch separation, or high levels of automation, a hopper bottom silo is the superior choice despite its higher initial cost.

What is the purpose of stiffeners on the outside of a steel silo?

External stiffeners are vertical steel beams attached to the silo walls. They provide crucial structural support, helping the corrugated steel sheets bear the vertical load from the grain and resist external forces like high winds.

Selecting and integrating the right grain storage silo is a foundational step in building an efficient and profitable food processing operation. From understanding the core engineering principles of structural design to implementing advanced systems for quality control, every decision impacts your bottom line. As experts with over 35 years of global experience, we specialize in designing and delivering comprehensive, end-to-end systems tailored to your specific needs. Request a Consultation for Your Turnkey Plant Project today to learn how our engineering expertise can protect your valuable commodities and optimize your production process.