In large-scale food manufacturing, achieving a perfectly consistent and homogenous product is not just a goal; it’s a necessity for quality control, brand reputation, and operational efficiency. The cornerstone of this process is the industrial mixture machine. Unlike domestic kitchen appliances, these powerful systems are engineered for high-volume, continuous operation, handling everything from fine powders to high-viscosity pastes with precision. This guide will explore the essential types of industrial mixers and provide the key criteria for selecting the right equipment for your food production line.

What is an Industrial Mixture Machine?

An industrial mixture machine, often called a blender or agitator, is a piece of equipment designed to combine, blend, emulsify, or homogenize multiple ingredients into a single, uniform substance. Its role in food manufacturing is critical, ensuring that every batch of product has the same texture, flavour, colour, and quality. The primary difference from a consumer-grade mixer lies in its scale, power, construction materials, and adherence to strict sanitary standards. The ultimate goal is to achieve complete product homogeneity, eliminating variations and ensuring a reliable final product for the market.

Core Components of an Industrial Mixer

While designs vary, most industrial mixers share four fundamental components that work in unison to process materials effectively:

- The Mixing Vessel: Often referred to as the trough, shell, or tank, this is the container that holds the product during the blending cycle. Its shape (e.g., U-shaped, V-shaped, conical) is specific to the mixing action required.

- The Agitator: This is the element that performs the physical mixing. Agitator designs are highly specialized and include ribbons, paddles, screws, or sigma blades, each engineered for different material types and desired outcomes.

- The Drive System: Comprising the motor and gearbox, the drive system provides the necessary power and torque to move the agitator through the product, especially when dealing with dense or viscous materials.

- The Discharge Mechanism: An efficient and sanitary valve or gate at the bottom of the vessel allows for the complete and controlled emptying of the mixed product, preparing it for the next stage of production.

Types of Industrial Mixture Machines for Food Processing

Selecting the correct type of mixer is entirely dependent on the physical characteristics of your ingredients. Factors such as particle size, density, viscosity, and whether the material is friable or sticky will dictate which machine design will deliver the best results.

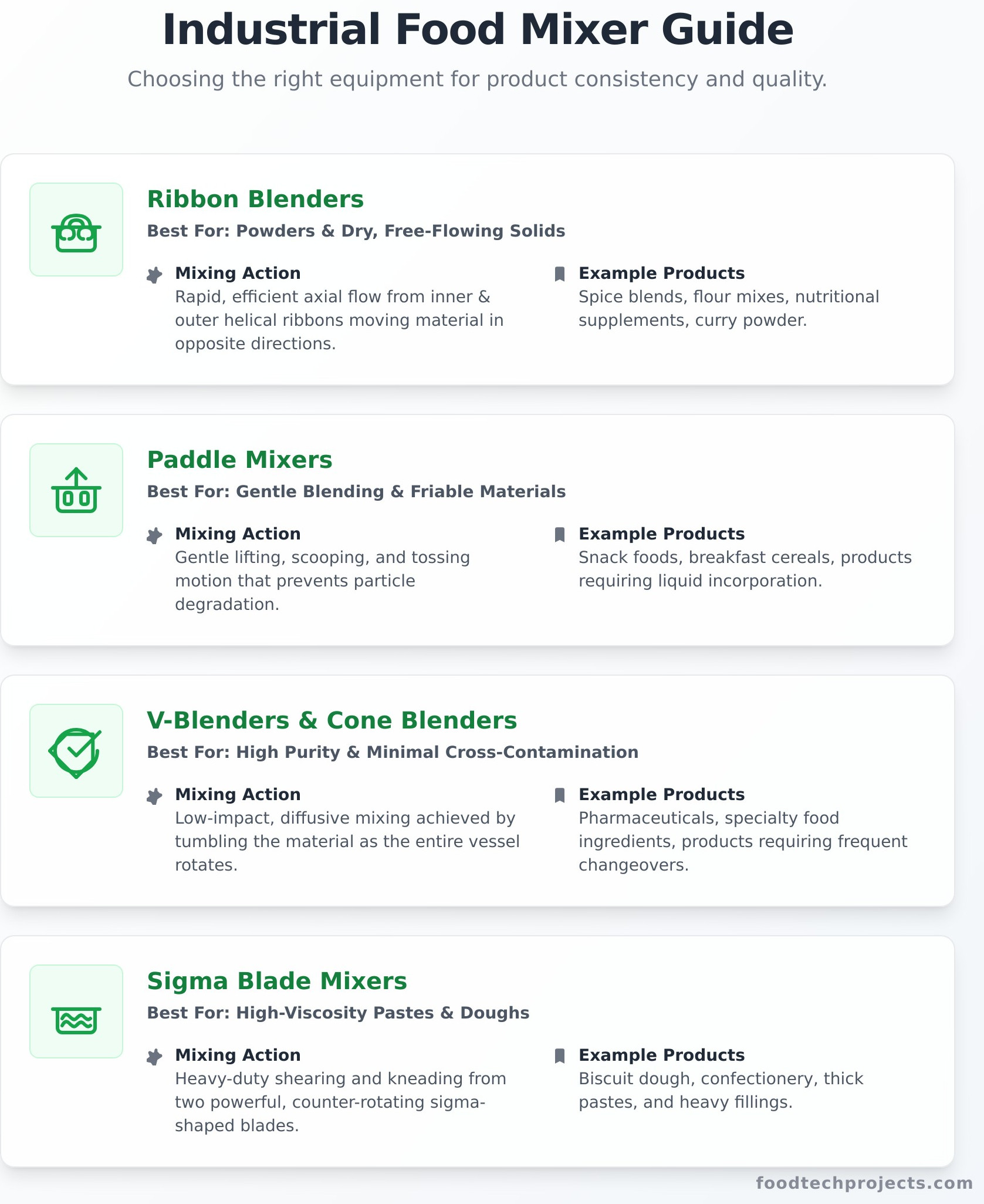

Ribbon Blenders: For Powders and Dry Solids

Ribbon blenders are one of the most common mixers in the food industry, ideal for rapidly and efficiently blending dry, free-flowing solids. They are perfectly suited for products like spice blends, curry powder, flour mixes, and nutritional supplements. The agitator consists of inner and outer helical ribbons that move material in opposite directions simultaneously, creating a thorough axial flow that ensures a homogenous mix in very short cycle times.

Paddle Mixers: For Gentle Blending and Friable Materials

When ingredients are delicate and can be damaged by aggressive mixing, a paddle mixer is the preferred choice. It is commonly used for snack foods, breakfast cereals, and other friable materials. The paddles are angled to provide a gentle lifting, scooping, and tossing motion, which prevents particle degradation. This design is also highly effective for incorporating liquids, oils, or fats into dry solids without creating lumps.

V-Blenders and Cone Blenders: For High Purity Blending

In the pharmaceutical and specialty food ingredient sectors where purity and minimal cross-contamination are paramount, V-blenders and cone blenders excel. These machines work by tumbling the material as the vessel rotates. This low-impact, diffusive mixing is precise and gentle. Because the design has no internal agitators or packing glands, these blenders are exceptionally easy to clean, making them ideal for applications requiring frequent changeovers between different products.

Sigma Blade Mixers: For High-Viscosity Pastes and Doughs

For the most demanding applications involving thick, sticky materials, the sigma blade mixer is the heavy-duty solution. It is engineered to handle high-viscosity products like biscuit dough, confectionery, pastes, and fillings. The two counter-rotating sigma-shaped blades create a powerful shearing and kneading action that stretches and folds the dense material, ensuring all ingredients are thoroughly incorporated into a uniform mass.

Key Selection Criteria for Your Mixture Machine

Adopting a systematic approach to specifying your equipment is crucial for a successful investment. A proper evaluation will help you balance performance requirements with your operational budget and long-term production goals.

Capacity, Batch Size, and Throughput Requirements

First, calculate the required working volume (in Liters or Kg) needed for each batch to meet your production targets. It is vital to match the machine’s capacity to your line’s overall output to avoid bottlenecks. Always consider your company’s future growth; selecting a machine with slightly larger capacity can provide valuable scalability as your demand increases.

Material of Construction and Sanitary Design

In food processing, hygiene is non-negotiable. Stainless Steel, typically grade SS 304 or the more corrosion-resistant SS 316, is the industry standard for all product contact surfaces. Look for machines with highly polished surfaces and smooth, crevice-free welds to prevent product buildup and bacterial growth. Features that facilitate easy and thorough cleaning, such as Clean-in-Place (CIP) compatibility, are essential for maintaining food safety standards.

Motor Power and Drive System Specifications

The drive system must be robust enough to handle the peak load of your specific product. Ensure the motor is correctly sized for your product’s density and viscosity to prevent stalling or damage. A Variable Frequency Drive (VFD) is a valuable addition, allowing for precise control over the agitator’s speed to optimize the mixing cycle for different products. For heavy pastes and doughs, a heavy-duty gearbox is essential for reliable, long-term performance.

Partner with Food Tech Projects for Your Mixing Solutions

Choosing the right machinery is a critical decision that impacts your entire production process. By partnering with an experienced manufacturer, you gain access to deep engineering expertise that ensures your equipment is perfectly suited to your needs. At Food Tech Projects, we leverage our 35+ years of experience to deliver comprehensive processing solutions, not just machines.

Custom Engineering for Your Unique Product

We understand that no two products are exactly alike. Our engineering team designs and fabricates industrial mixers that are tailored to your specific ingredients, processes, and facility constraints. We specialize in integrating our equipment seamlessly into your existing production line, offering full turnkey project support from the initial design and consultation phase through to final installation and commissioning.

Uncompromising Commitment to Quality and Reliability

Our machinery is built in state-of-the-art facilities to withstand the rigors of continuous industrial production. We use only high-grade materials and proven components to ensure maximum uptime, reliability, and a long service life for your investment. As a global supplier, we provide comprehensive support to clients around the world. To start building a more efficient and consistent production line, Request a consultation for your mixing application.

Frequently Asked Questions

What is the difference between an industrial blender and a mixer?

In the industrial context, the terms “blender” and “mixer” are often used interchangeably. Both refer to equipment designed to combine ingredients. However, “blender” is more commonly used for dry powder applications (like a Ribbon Blender), while “mixer” can be a broader term that also includes equipment for high-viscosity pastes and doughs (like a Sigma Mixer).

How do you determine the right mixing time for a specific product?

The optimal mixing time is determined through testing and analysis. It depends on the ingredients, batch size, and agitator speed. The goal is to reach the point of homogeneity without over-mixing, which can waste energy or damage the product. Lab testing or pilot runs are often conducted to establish the precise cycle time for a new product.

What safety features are essential on an industrial mixture machine?

Essential safety features include safety grates or covers with limit switches that automatically stop the machine if opened during operation, emergency stop buttons, and motor overload protection. Proper guarding around all moving parts and lock-out/tag-out provisions for maintenance are also critical.

How can I ensure my mixture machine meets food-grade sanitary standards?

Ensure the machine is constructed from food-grade stainless steel (SS304 or SS316), has a sanitary design with no sharp corners or crevices where bacteria can grow, and features polished, easy-to-clean surfaces. Certifications from bodies like EHEDG or 3-A are a strong indicator of a high sanitary standard.

Can a single mixture machine handle both dry powders and wet pastes?

While some versatile mixers exist, most are optimized for a specific range of material properties. A machine designed for light powders, like a V-blender, will not have the power to handle a heavy paste. Conversely, a high-shear mixer for pastes might degrade a delicate powder. It’s best to select a machine specifically designed for your primary application.

What is the typical maintenance schedule for an industrial mixer?

A typical schedule includes daily cleaning and inspection, weekly checks of lubrication levels and safety switches, and monthly inspection of seals, gaskets, and drive components like belts or chains. An annual service by a qualified technician is recommended to check bearings, gearbox oil, and motor performance.

Investing in the right industrial mixture machine is fundamental to achieving superior product quality and maximizing production efficiency. By understanding the different types of technology and carefully evaluating your specific process requirements, you can select a solution that delivers consistent results and a strong return on investment for years to come. Our team of seasoned experts is ready to help you navigate these choices and engineer the ideal solution for your facility. Contact our engineers to discuss your project requirements.