This guide breaks down the key factors that determine the price of a noodles manufacturing machine, helping you budget for your industrial production needs.

Why You Can’t Find One Simple ‘Noodles Machine Price’ Online

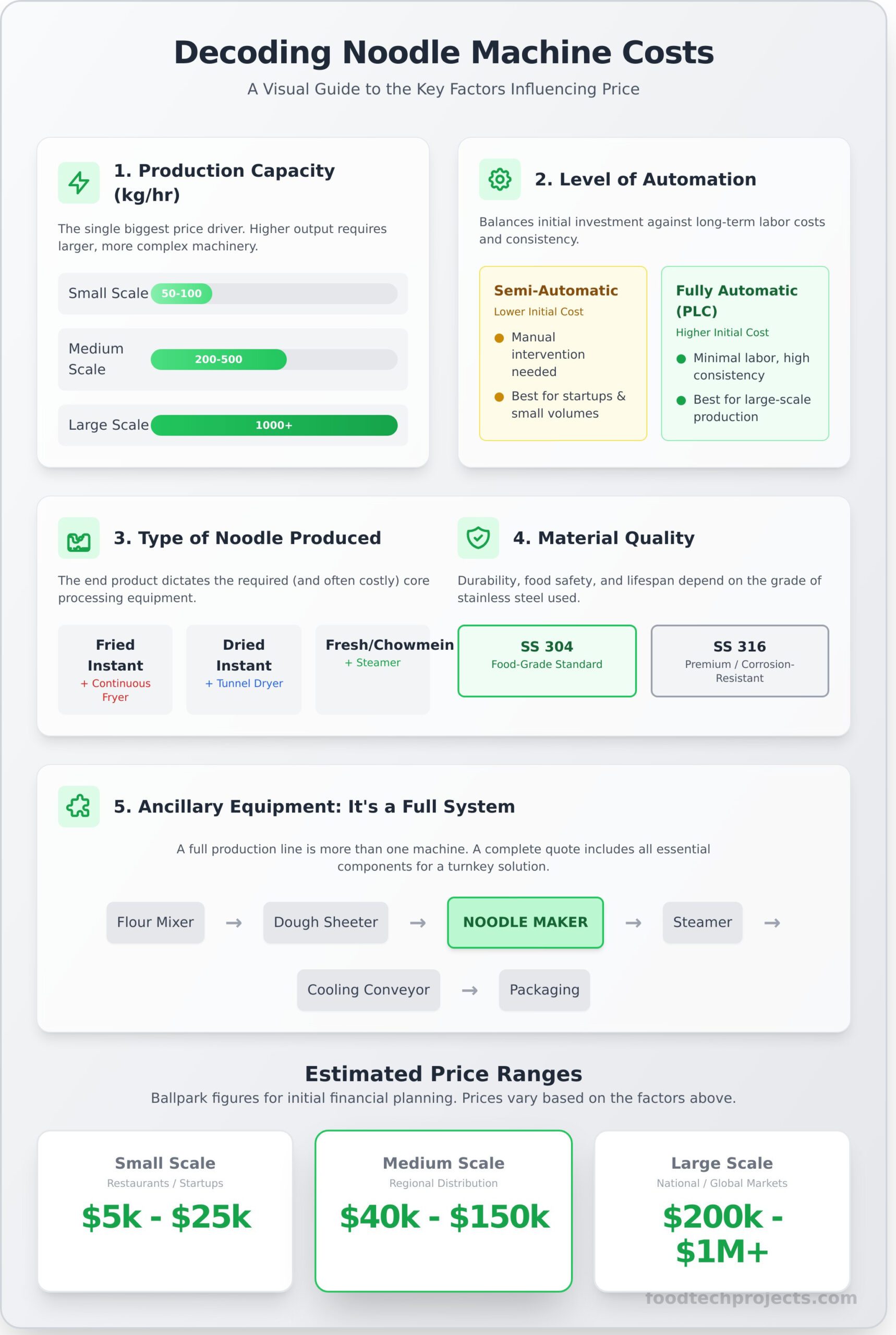

When searching for the price of industrial noodle machines, you will likely encounter a wide and often confusing range of figures. The price is not a simple sticker value because it fundamentally depends on your specific production goals. A standalone machine designed for a single task is vastly different from a complete, integrated production line. Furthermore, online listings often show base models without the essential ancillary equipment required for full operation. This guide explains the critical variables so you can formulate an accurate budget for your project.

Standalone Machine vs. Full Production Line

Understanding the distinction between a single machine and a full production line is the first step. Standalone machines are engineered to perform one specific function, such as dough pressing or noodle cutting. In contrast, a complete production line integrates all stages of the manufacturing process, from raw material mixing and dough sheeting to steaming, frying or drying, cooling, and packaging. A complete line offers significantly higher efficiency, consistency, and automation. Ultimately, your required production output—measured in kilograms per hour—will determine which option is the right investment for your operation.

Key Factors That Determine Noodles Manufacturing Machine Price

Understanding the following factors is crucial for requesting and evaluating an accurate price quote for your noodle manufacturing equipment. Each of these elements directly impacts the machine’s performance, operational longevity, and final investment cost.

1. Production Capacity (kg/hour)

Production capacity is the most significant price driver for any industrial food processing machinery. The required output dictates the size, power, and complexity of the entire line. Capacities are generally categorized as follows:

- Small Scale: 50-100 kg/hr, suitable for smaller businesses, regional suppliers, or market-testing new products.

- Medium Scale: 200-500 kg/hr, designed for growing operations aiming for wider distribution.

- Large Scale: 1000+ kg/hr, built for mass production and serving national or international markets.

2. Level of Automation

The degree of automation directly influences both the initial capital investment and long-term operational costs. Semi-automatic lines require more manual labor for tasks like transferring dough or managing packaging. Fully automatic lines, on the other hand, utilize integrated systems like PLC (Programmable Logic Controller) controls to manage the entire process, reducing labor costs, minimizing human error, and improving product consistency. While PLC systems increase the initial price, they offer greater precision and efficiency for large-scale operations.

| Feature | Semi-Automatic Line | Fully Automatic Line |

|---|---|---|

| Key Features | Requires manual intervention between stages. Basic control panels. | Integrated PLC controls, sensors, and minimal manual labor. |

| Price Impact | Lower initial investment. | Higher initial investment. |

| Best For | Startups, smaller production volumes, businesses with available labor. | Large-scale producers, businesses focused on consistency and low long-term labor costs. |

3. Type of Noodles Produced

The end product dictates the necessary machinery. Different types of noodles require specialized, and sometimes costly, processing equipment:

- Instant Fried Noodles: Require a large, continuous frying machine, which is a significant component of the line’s cost.

- Instant Dried Noodles: Need a multi-level drying chamber or tunnel dryer to remove moisture efficiently without frying.

- Fresh or Chowmein Noodles: Have a simpler process, typically involving mixing, sheeting, cutting, and steaming, resulting in a less expensive line.

4. Material Quality and Construction

The durability and safety of your machinery depend on its construction. Food-grade stainless steel (SS 304) is the industry standard for parts that come into contact with the product. For processing environments with high salt or corrosive elements, higher-grade steel like SS 316 may be necessary, which increases the cost. The quality of components such as motors, bearings, and electronics also affects the machine’s reliability, lifespan, and overall price.

5. Ancillary Equipment Included

A complete noodle production line includes far more than just the noodle maker itself. An accurate quote must account for all essential and optional ancillary machines that form a cohesive system. Essential machines typically include a flour mixer, dough sheeter, and a steamer. Optional but often necessary add-ons can include a cooling conveyor, a seasoning system, and an automated packaging machine. For a comprehensive system that covers every step of production, it’s best to work with a supplier that offers integrated solutions. Need a complete solution? Explore our turnkey plants.

Estimated Price Ranges for Noodle Production Lines

While a precise quote requires a detailed consultation, the following ballpark figures can help with initial financial planning. Please note that these are general estimates, and prices will vary based on the factors discussed above, as well as freight, installation, and other variables.

Small-Scale & Commercial Machines

These machines are typically designed for restaurants, catering businesses, or small-scale startups. They often include basic forming, cutting, and sometimes boiling functions. The estimated price range for this category is approximately $5,000 – $25,000.

Medium-Scale Industrial Lines

Designed for dedicated noodle manufacturing businesses aiming for regional distribution, these lines offer higher capacity and more automation. They often include integrated steaming, drying or frying, and cooling systems. The estimated price range is typically between $40,000 and $150,000.

Large-Scale, Fully Automatic Turnkey Plants

Built for mass production targeting national or international markets, these are complete end-to-end solutions. They include everything from raw material handling and automated mixing to final case packaging. The investment for these comprehensive plants can range from $200,000 to over $1,000,000.

How to Get an Accurate Quote for Your Project

A reliable and experienced manufacturer will not provide an instant price. Instead, they will ask detailed questions about your project to provide a quote that accurately reflects your needs. To ensure you receive a relevant and precise price, it is best to prepare your project details before initiating a consultation.

Information to Prepare Before Contacting a Supplier

- Your desired production capacity, specified in kilograms per hour or kilograms per day.

- The exact type of noodles you plan to produce (e.g., fried instant, dried, fresh).

- Your available factory space, including layout dimensions (length, width, and height).

- Your target budget and desired level of automation.

Partner with an Experienced Manufacturer

Choosing the right supplier is as important as choosing the right machine. Food Tech Projects has over 35 years of experience in designing, manufacturing, and commissioning food processing plants worldwide. We provide end-to-end turnkey solutions, engineering production lines that are tailored to your specific operational needs and financial budget, ensuring a reliable and profitable investment.

Frequently Asked Questions

What is the ROI on a noodles manufacturing machine?

The Return on Investment (ROI) depends heavily on factors like your production volume, operational efficiency, raw material costs, and the market price of your final product. A high-capacity, automated line can offer a faster ROI through lower labor costs and higher output, despite the larger initial investment.

Can one machine make different types of noodles?

Some machines offer flexibility through interchangeable cutting dies to produce noodles of different widths and shapes. However, producing fundamentally different types, such as fried versus non-fried noodles, requires entirely different sets of equipment (e.g., a fryer versus a dryer).

How much factory space is required for a noodle production line?

Space requirements vary dramatically with capacity. A small-scale line might fit within a few hundred square feet, while a large-scale, fully automatic plant can require several thousand square feet to accommodate the linear flow of processing, from mixing to packaging.

What kind of after-sales support is included in the price?

Reputable manufacturers typically include a warranty on parts and labor. Additional support, such as installation supervision, operator training, and ongoing technical service, should be clarified in the quotation. At Food Tech Projects, we provide comprehensive support to ensure your plant operates smoothly.

Do you provide installation and training services?

Yes, as a provider of turnkey solutions, we offer complete project management that includes equipment installation, commissioning, and training for your operational staff to ensure you can maximize the performance and longevity of your production line.

Ready to move from planning to production? Partner with an industry leader to engineer a noodle manufacturing line that meets your exact specifications and budget. Request a customized quote for your noodle plant today.